YW non-clogging submerged sewage pumps are new generation of products developed on the base of the advanced technology at home and abroad as well as the operational characteristics of pumps at home. Featuring distinguished effect in energy conservation, winding and clogging resistance, it is especially suitable for handling sewage containing solid particles and long fibre.

Model :

YWD25-8-22-1.1Imported caliber (DN) :

25Export caliber (DN) :

25Rated flow (m³/h) :

8Rated head (m) :

22Motor speed (rpm) :

2900Motor power (kw) :

1.1Material :

Cast ironFOB Price (USD$) :

377Non-Clogging Submersible sewage pump

Technical parameters:

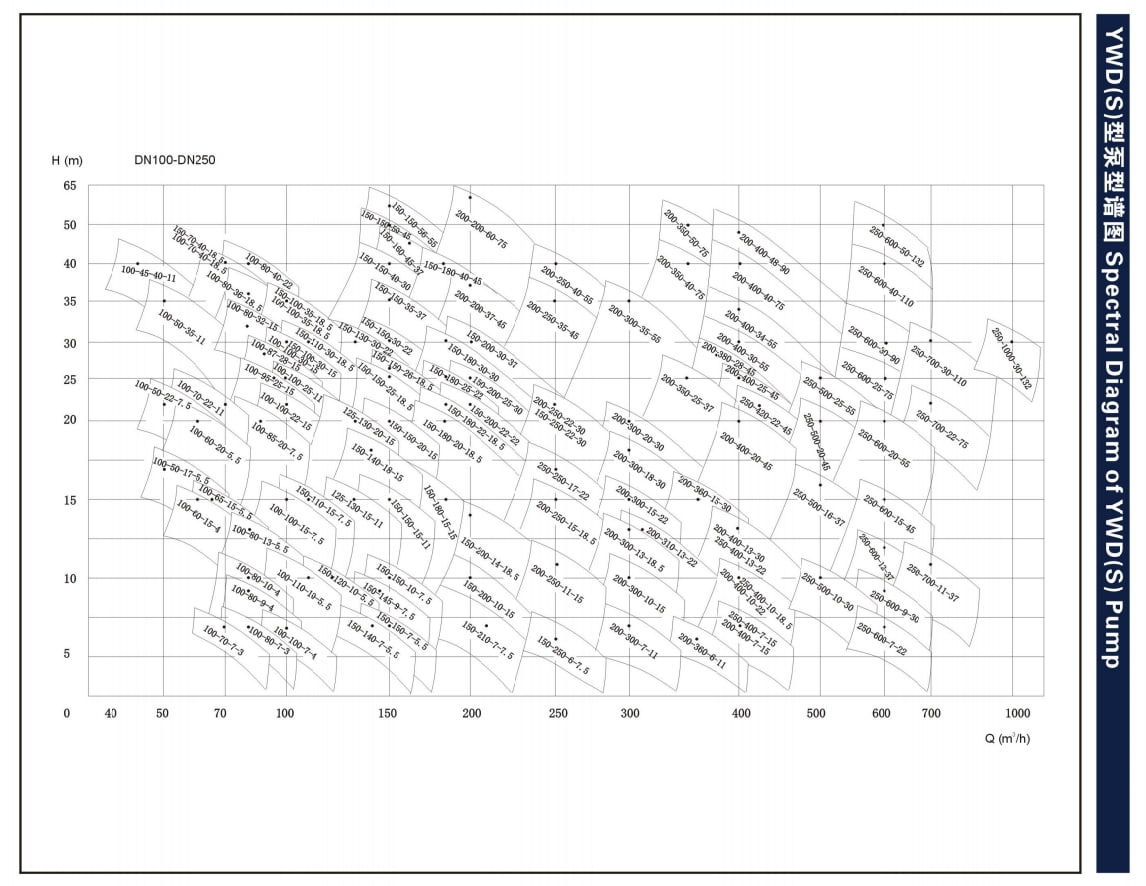

flow, Q: maximum 2600 m³/h

Head, H: maximum 60 m

Medium temperature: -15℃ - 60℃

System pressure: max. 16 bar

Overview

YW non-clogging submerged sewage pumps are new generation of products developed on the base of the advanced technology at home and abroad as well as the operational characteristics of pumps at home. Featuring distinguished effect in energy conservation, winding and clogging resistance, it is especially suitable for handling sewage containing solid particles and long fibre.

Provided with original impeller structure and latest mechanical seal, this pump can be used to effectively handle medium containing solid substances and long fibre. Compared with the conventional impellers, the impeller on this pump uses single-channel or double-channel, which is similar to an elbow of the same section and fitted with reasonable spiral housing to feature high efficiency and outstanding throughput capacity. Impellers have been subject to dynamic and static balancing test so that there cannot be any vibration in operation.

This pump is given sophisticated hydraulic performance, with all performance indexes In accordance with relevant standard specifications. Ever since the products were put into market, they have been greatly recognized by the mass customers for their distinctive efficiency, reliable performance and consistent quality.

Service Conditions

1. Temperature of medium not over 60℃ , gravity 1~1.3kg/dm*, PH within 5~9.

2. Normally, pump must work within the range of its head so that motor won't be overloaded. If it is to be used in full head,please point out separately when placing an order for our convenience to make the right productfor you.

3. In the process of operation, motor shouldn't exceed its rated current.

4. In case of any special requirements in tempe rature or medium, please detail the medium to be delivered when placing an order for our convenience to make the right product for you.

Features

1. Designed with large-flow and antl-clogging hydraulic components to have greatly improved the throughput capacity of sewage. It can handle fibre material with a diameter up to 5 times of that of pump and solid particles with a diameter up to 50% of that of pump.

2.Reasonable design, good matching of motor, high efficiency and remarkable energy conservation.

3. Double-channel mechanical seal in series, made of durable wear-resisting hard tungsten carbide to enable pump working safely for continuously over 8,000 hours.

4.Compact structure, small volume, easy to move and install.

5. If requested by users, it can be fitted with an automatic liquid level control cabinet to automatically control the start and stop of pump according to the variation of the required liquid level, with no need of a special person to care about it, making the operation quite easy.

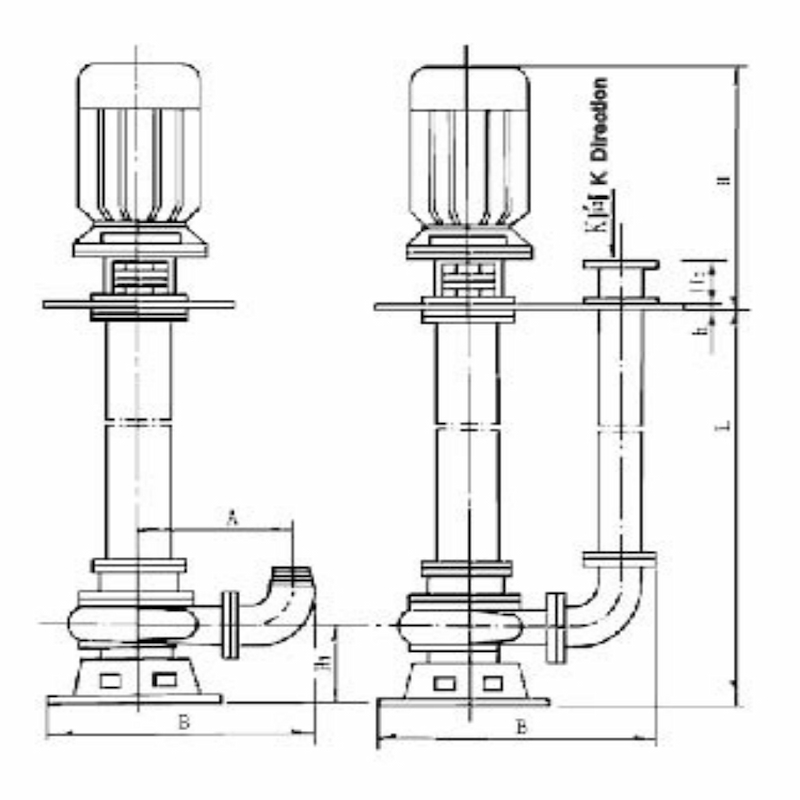

6. Vertical structure. While in operation, as the body of pump is submerged into the liquid, and there is no need for air emptying, it is fairly easy to start. Also, it can be leak tight, and the depth underwater can be 0.5~7m.

7. Advanced and reliable coupling structure, pump and motor connected by a coupling with precise pump shaft dimensions to ensure the smooth operation and enough safety coefficient of pump.

8. Motor is assured to work not overloaded within the range of head.

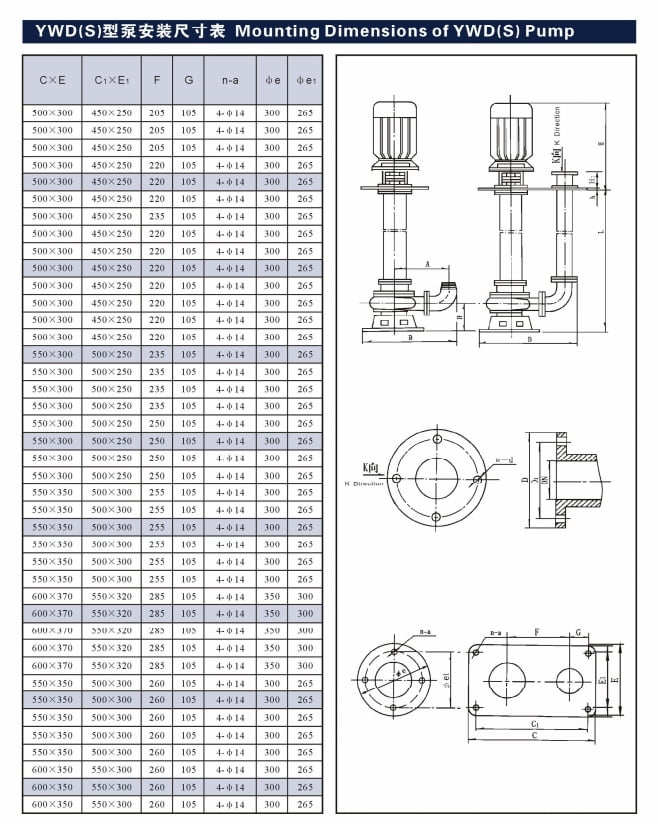

9. Pump can be installed with one or two pipes, the support can be installed with round or square disc.

Applicability

1.Drainage of seriously polluted wastewater in industrialand commercial areas.

2. Drainage system in municipal sewage plant.

3. Sewage drainage station in residential areas.

4. Drainage station in national defense system.

5. Sewage drainage in hospitals and hotels.

6. Municipal and construction projects.

7. Used as auxiliary equipment in exploration and mining.

8. Methane pool and farmland irrigation in rural areas.

9. Water supply equipment in waterworks.