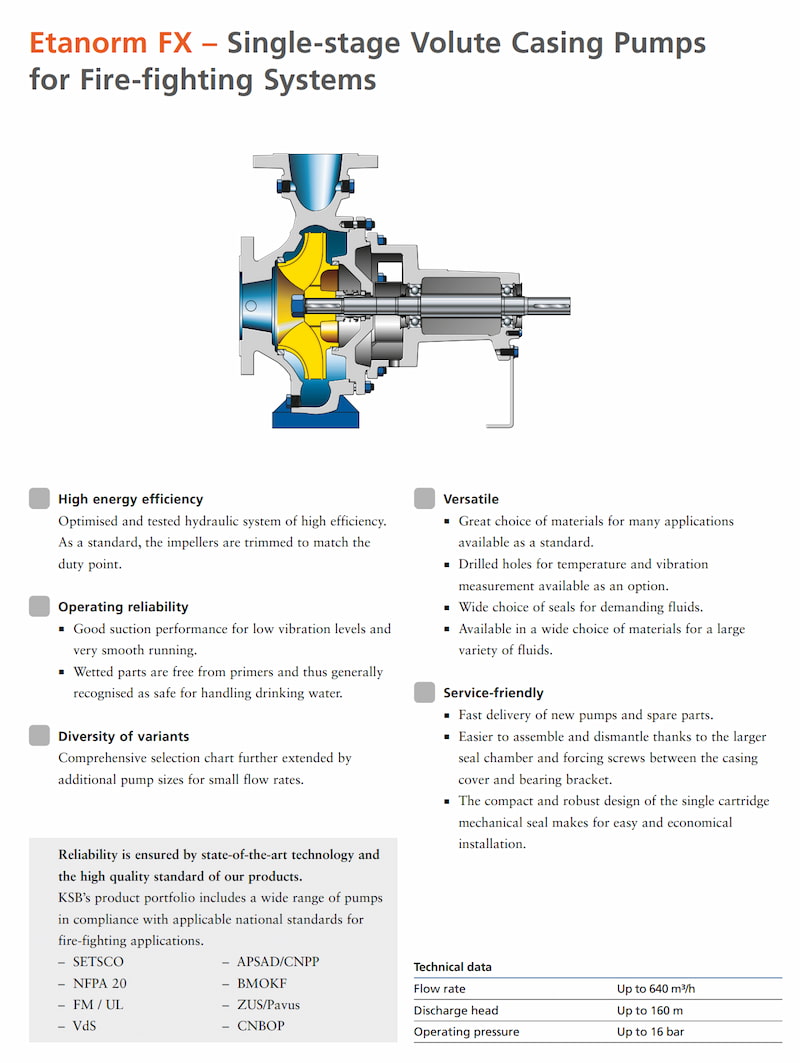

KSB ETN Extended Coupling Single Stage End Suction Centrifugal Pump

Horizontal type, using extended coupling, single-stage radial split volute (pump size larger than 125 adopts two-stage design) adopts back-pumping design, with replaceable shaft sleeve/shaft protection sleeve and replaceable pump body sealing ring, and the design conforms to ATEX;

Model :

ETN 200-150-400 GGRated flow (m³/h) :

420Rated head (m) :

35Motor speed (rpm) :

1450Motor power (kw) :

55Material :

All cast ironFOB Price (USD$) :

7504Extended Coupling Single Stage End Suction Centrifugal Pump

Use/maintenance

The maximum ambient temperature of the water pump is 40℃.

In order to prevent the motor temperature from being too high, the maximum allowable number of start-stop times per hour for pumps under 11KW is 15 times, and the maximum allowable number of start-stop times per hour for pumps above 11KW is 6 times.

For grease lubricated water pump bearings and motor bearings with oil nozzles, grease should be replenished regularly every 4000 hours (about 6 months). 2# or 3# high temperature lithium base grease can be used.

For water pump bearings lubricated with thin oil, the oil needs to be changed after 300 hours of initial operation, and then every 3000 hours, and at least once a year.

After 24 hours of initial operation, the coupling alignment should be rechecked. Thereafter, it will be reviewed every 2000 hours (3 months).

When the medium temperature is -30℃~70℃, the minimum flow rate is greater than 15% of the rated flow rate; When the medium temperature is 70℃~140℃, the minimum flow rate is greater than 25% of the rated flow rate.

Stop the water pump for a long time, and start it regularly once a month for 1 minute each time.

When the water pump has been shut down for more than 3 months, it is necessary to manually loosen the pump shaft before starting, and then start it again after confirming that there is no sticking.

When the water pump is shut down for more than one year, replace all rubber seals.

Bearing temperature is not allowed to exceed 90℃.

Main application

Convey colorless or corrosive liquid that will not cause chemical or mechanical corrosion to pump materials.

water-supply system

cooling circuit

Swimming pool equipment

fire extinguisher system

irrigation equipment

pumping appliance

heating plant

air conditioning equipment

Rainmaker

Pumped medium

seawater

Brackish water

Drinking Water

high-temperature-hot-water

domestic water

Fire water

saline water

cleanser

condensated water

Application Cases

Water treatment: widely used in sewage treatment plants and desalination plants to help transport large flows, sewage or clean water.

Chemical industry: used to transport chemicals or solutions to ensure safe and efficient delivery of chemical fluids.

HVAC system: used as a cooling water pump in the building's water supply and air conditioning system to ensure efficient operation of the equipment.

Construction and municipal engineering: used for water extraction during construction or in municipal water supply systems to ensure stable water supply.