GW non-clogging pipeline sewage pumps are new generation of products developed with the advanced technology abroad and on the base of the operational characteristics of pumps at home.Their hydraulic model is the same as WQsewage pumps.Featuring distinguished effect in energy conservation, winding and clogging resistance, it is especially suitable for handling sewage containing solid particles and long fibre.

Model :

GW25-8-22-1.1Imported caliber (DN) :

25Export caliber (DN) :

25Rated flow (m³/h) :

8Rated head (m) :

22Motor speed (rpm) :

2900Motor power (kw) :

1.1Material :

Cast ironFOB Price (USD$) :

233Non-Clogging Pipeline Sewage Pump

Technical parameters:

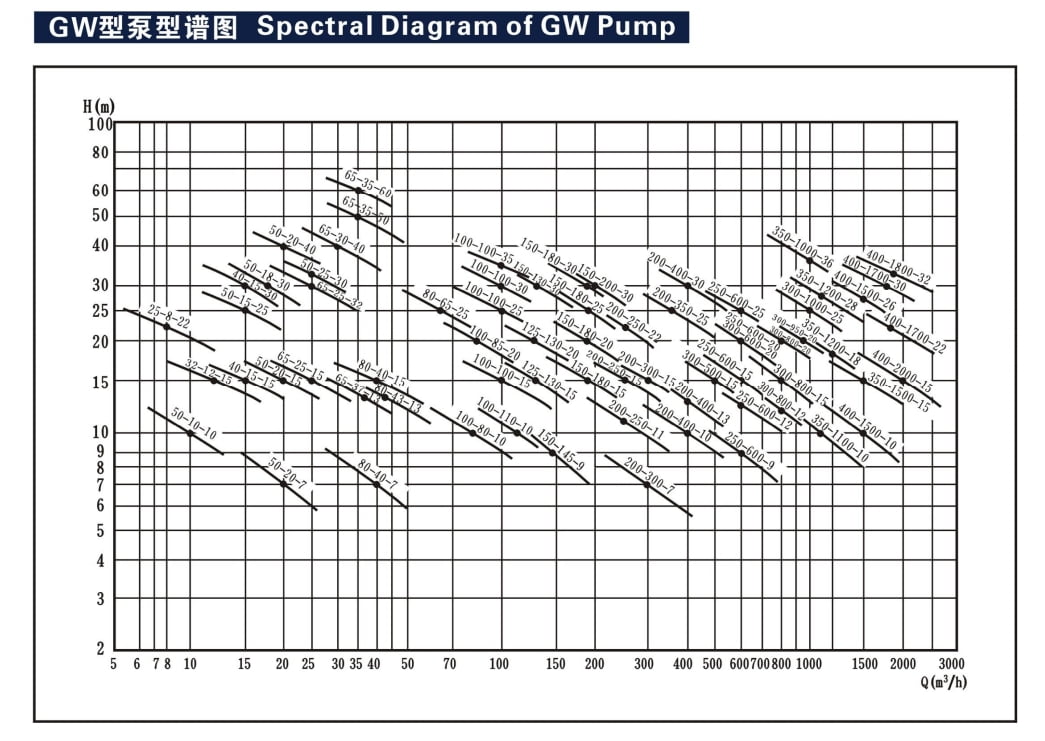

flow, Q: maximum 2600 m³/h

Head, H: maximum 60 m

Medium temperature: -15℃ - 60℃

System pressure: max. 16 bar

Overview

GW non-clogging pipeline sewage pumps are new generation of products developed with the advanced technology abroad and on the base of the operational characteristics of pumps at home.Their hydraulic model is the same as WQsewage pumps.Featuring distinguished effect in energy conservation, winding and clogging resistance, it is especially suitable for handling sewage containing solid particles and long fibre.

Provided with original impeller structure and latest mechanical seal, this pump can be used to effectively handle medium containing solid substances and long fibre. Compared with the conventional impellers, the impeller on this pump uses single-channel or double-channel, which is similar to an elbow of the same section to display outstanding throughput capacity. Plus the reasonable spiral housing to feature high efficiency. Impellers have been subject to balancing test so that there cannot be any vibration in operation.

This pump is given sophisticated hydraulic performance, with all performance indexes in accordance with relevant standard specifications. Ever since the products were put into market, they have been greatly recognized by the mass customers for their distinctive efficiency, reliable performance and consistent quality.

Features

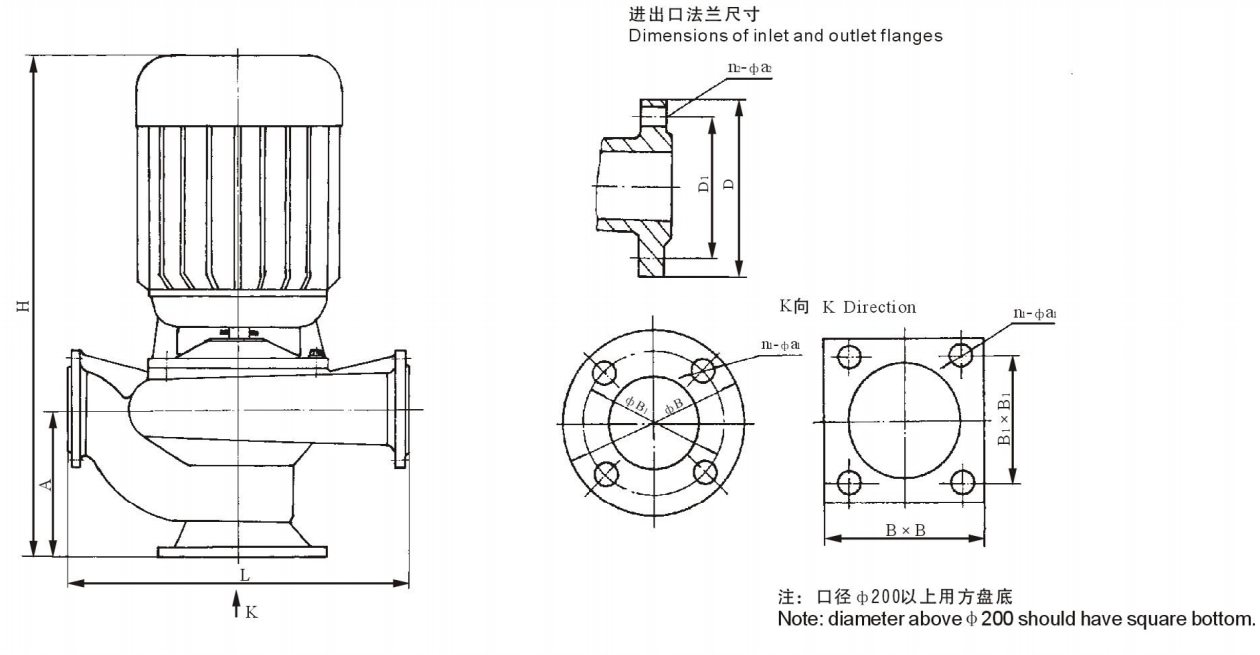

1. Vertical single entry single stage centrifugal sewage pump,with inlet and outlet centerlines on the same horizontal, and the same inlet and outlet flanges to enable quite easy installation and small occupation, so that it can be mounted at any position in pipeline, just like a valve can.

2. With pump and motor close coupled and coaxial, it is a product of mechanical and electrical integration to feature compact structure and consistent performance.

3. Designed with large-flow and anti-clogging hydraulic components to have greatly improved the throughput capacity of sewage, it can handle fibre material with a length up to 5 times of pump diameter and solid particles with a diameter up to 50% of pump diameter.

4. Reasonable design, good matching of motor, high efficiency and remarkable energy conservation.

5.Mechanical seal made of durable wear-resisting hard tungsten carbide to enable pump working safely for continuously over 8,000 hours.

6. Outstanding hydraulic performance. high overall efficiency and low running noise.

7. If provided with a protective cover at the fan blade of motor,it can work outdoors, with no need of a pump room for the economy of construction cost.

8. Service within the range of head to ensure motor not overloaded.

Applicability

1.Drainage of seriously polluted wastewater in industrial and commercial areas.

2.Drainage system in municipal sewage plant.

3. Sewage drainage station in residential areas.

4.Drainage station in national defense system.

5.Sewage drainage in hospitals and hotels.

6.Municipal and construction projects.

7. Used as auxiliary equipment in exploration and mining.

8. Methane pool and farmland irrigation in rural areas.

9.Water supply equipment in waterworks.

Service Conditions

1. Temperature of medium not over 60℃, gravity 1.0~1.3kg/dm,PH within 5~9.

2. As pump and motor form up an integral structure, the operating ambient temperature of pump shouldn't exceed 40℃, height above sea level not over 1,000m, and relative humidity not over 95%.

3. Normally, pump must work within the range of its head so that motor won't be overloaded. If it is to be used in full head, please point out separately when placing an order for our convenience to make the right product for you.

4. In the process of operation, the current of motor shouldn't exceed its rated value.