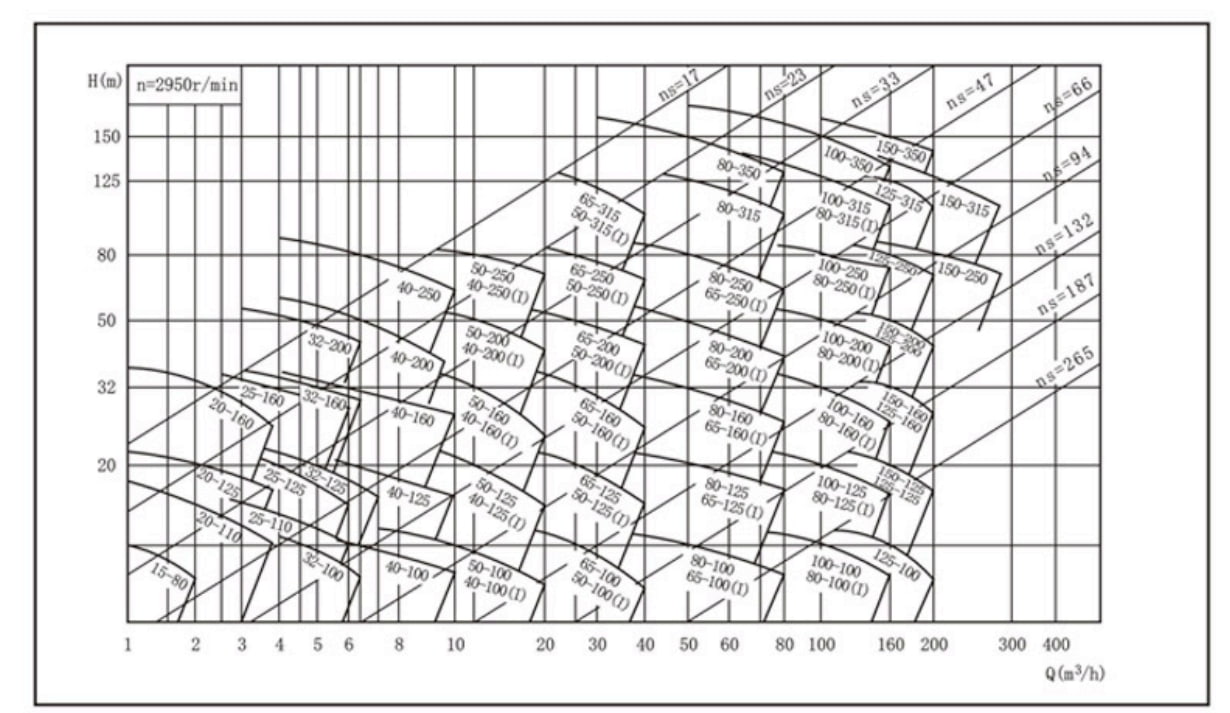

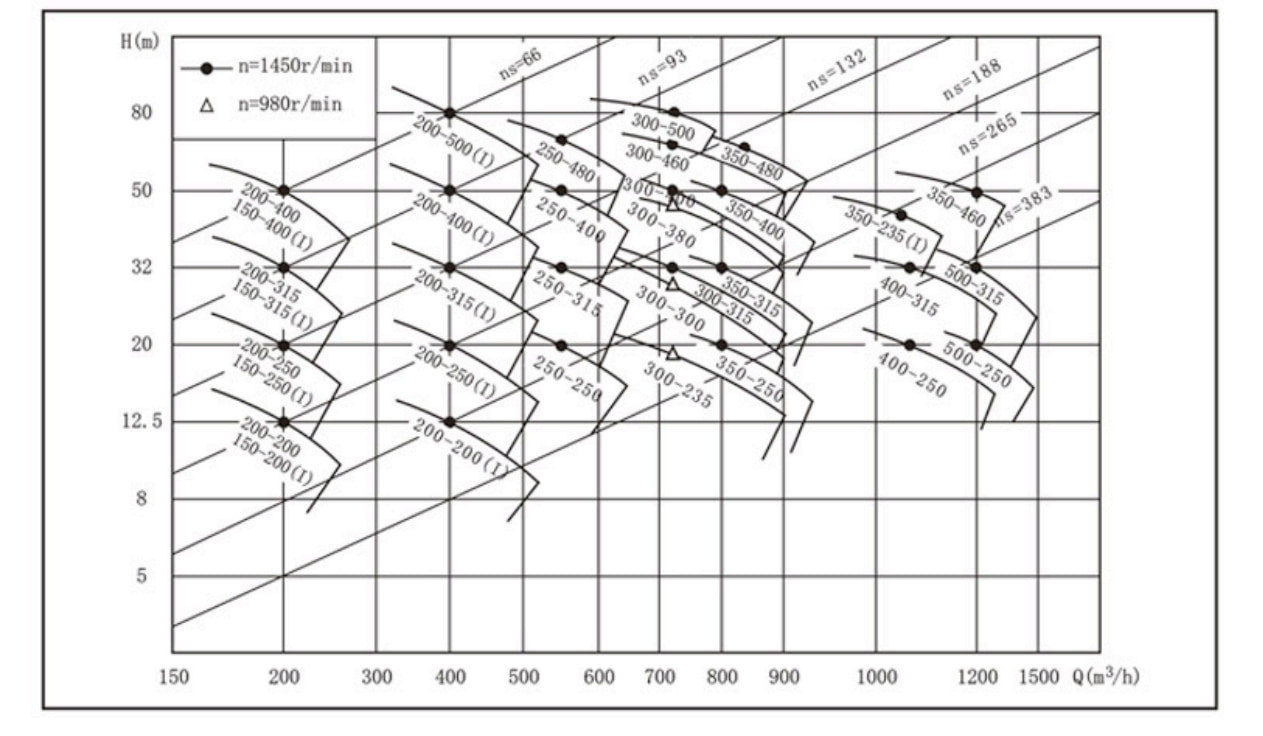

ISH and ISHPseries horizontal centrifugal pumps are optimally designed with domestic advanced hydraulic models,which are based upon the performance parameters of IS and IRcentrifugal pumps, and ISO2858 standard. They are a new-generation of highly effective and energy-saving horizontal pumps.

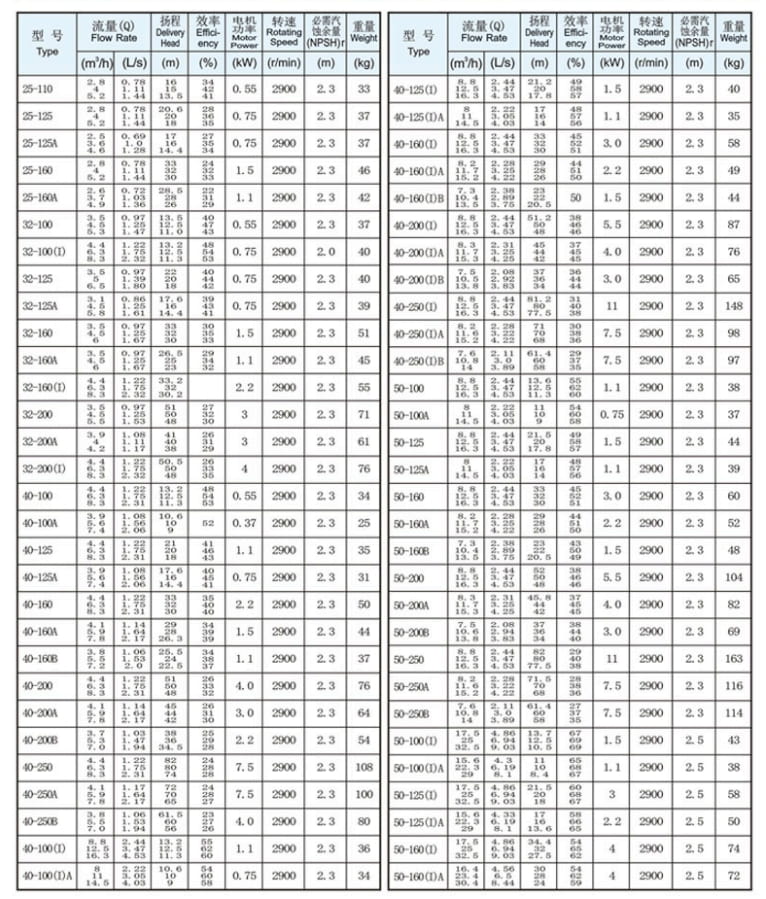

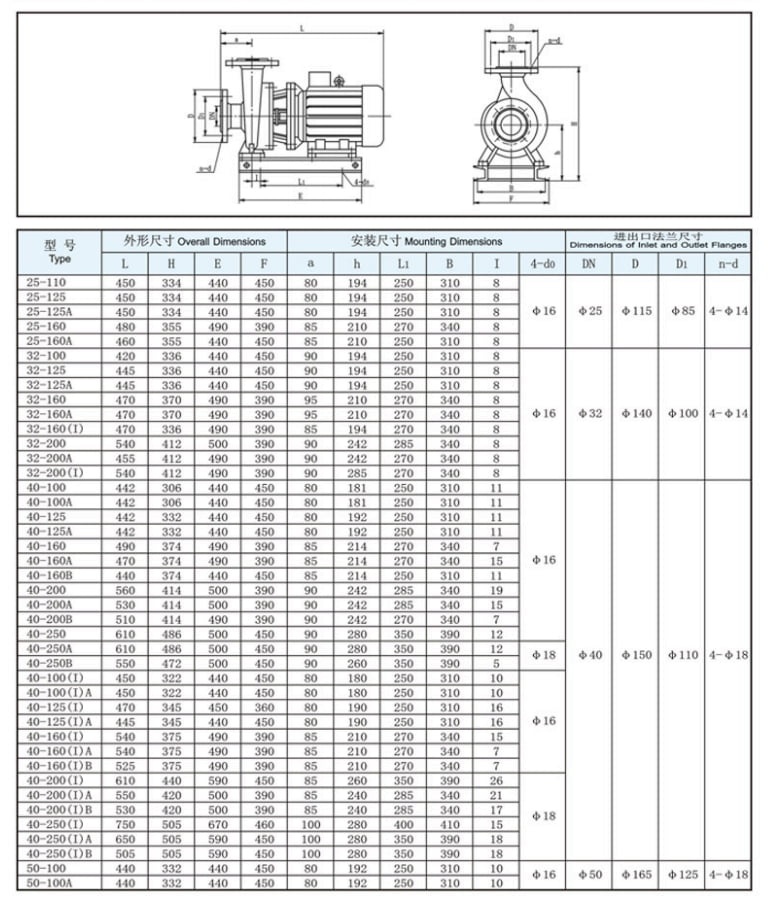

Model :

ISH25-125Imported caliber (DN) :

25Export caliber (DN) :

25Rated flow (m³/h) :

4Rated head (m) :

20Motor speed (rpm) :

2900Motor power (kw) :

0.75Material :

Cast ironFOB Price (USD$) :

220horizontal centrifugal pump

Technical parameters:

Flow, Q: max. 1450 m³/h

Head, H: max. 156 m

Medium temperature: -20℃ - 120℃

System pressure: max. 16 bar

Overview

ISH and ISHPseries horizontal centrifugal pumps are optimally designed with domestic advanced hydraulic models,which are based upon the performance parameters of IS and IRcentrifugal pumps, and ISO2858 standard. They are a new-generation of highly effective and energy-saving horizontal pumps.

Usage

ISH horizontal centrifugal pumps are used to handle cleanwater and liquids similar to water in physical and chemical properties. They are applicable to industrial and city water supply and drainage, pressurized water supply in high-rise constructions,ships, garden irrigation, fire-fighting pressurization,distant transportation,heating,ventilating,refrigeration circulation, and bathrooms for cyclic pressurization of cold and hot water, and other equipments. Temperature of service medium not exceeding 85℃.

ISHP horizontal chemical centrifugal pumps are applicable to handling corrosive liquids in the industries of petroleum,chemical, metallurgy, electric power, papermaking, foodstuff,pharmaceutical and synthetic fiber etc. Service temperature-20~105℃.

Features

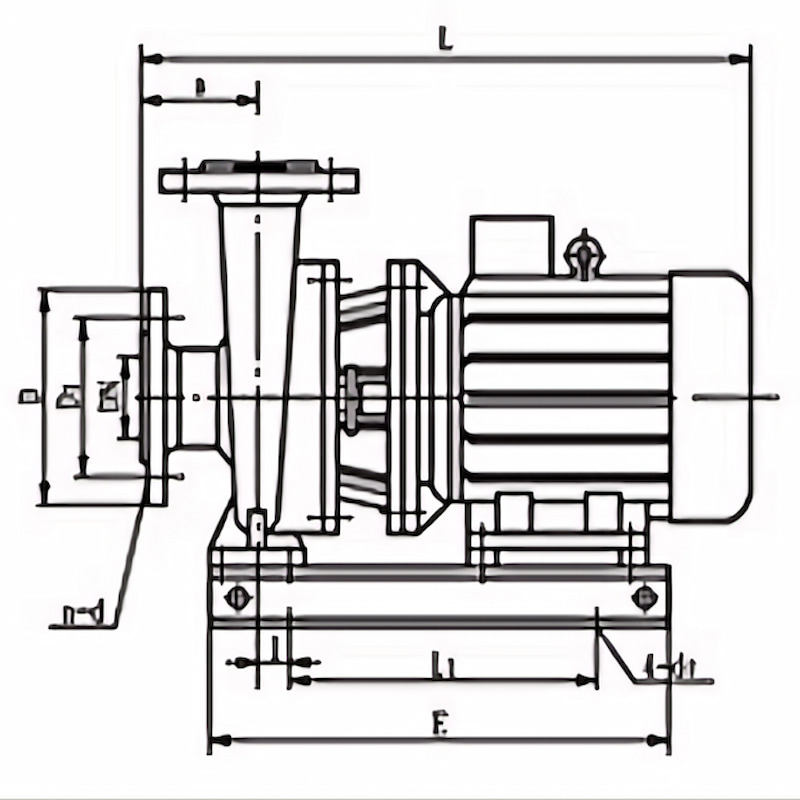

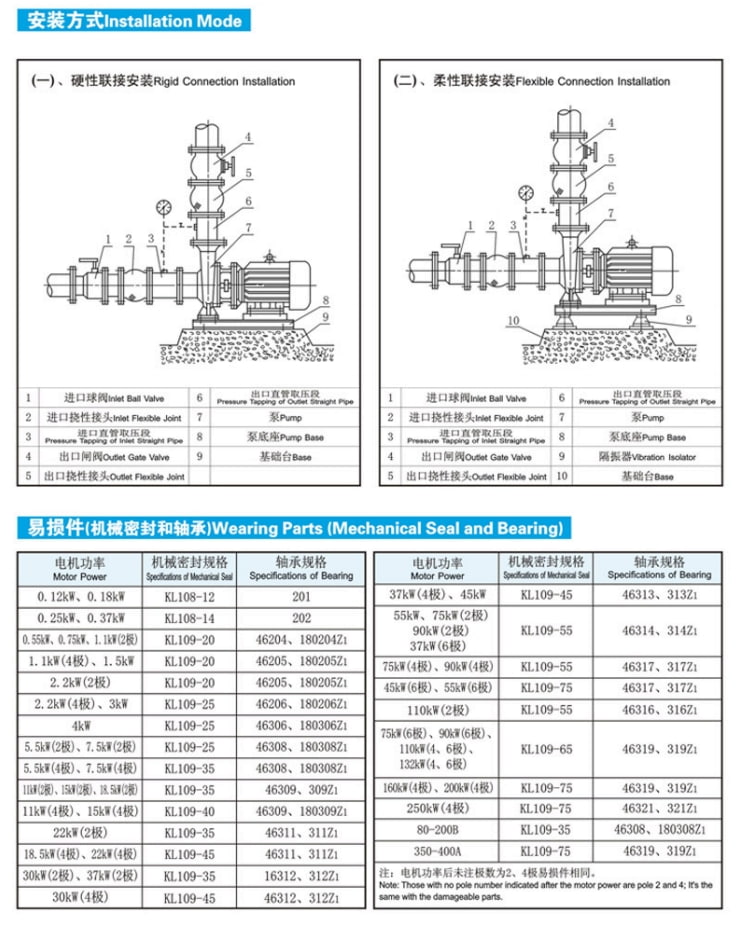

1. Compact structure. Horizontal structure, integration of motor and pump. appealing appearance and less occupation space.Compared with ordinary horizontal pumps, it saves occupation space by 30%. If IP54 outdoor motor is used, it can be used outdoors with no need of a pump room.

2.Smooth operation, little noise and high concentricity of components. Close coupled motor and pump to have simplified intermediate structure and increased running stability. Impeller is provided with excellent dynamic and static balance to obtain no vibration and low noise in operation, which has lengthened the service life of bearings and improved the service conditions.

3. Use of quality mechanical seal for shaft seal, rotating and stationary seal rings made of hard alloy to effect abrasion resistance, leak tightness and long service life.

4. Use of advanced hydraulic model to feature high efficiency and sound pcrformancc.

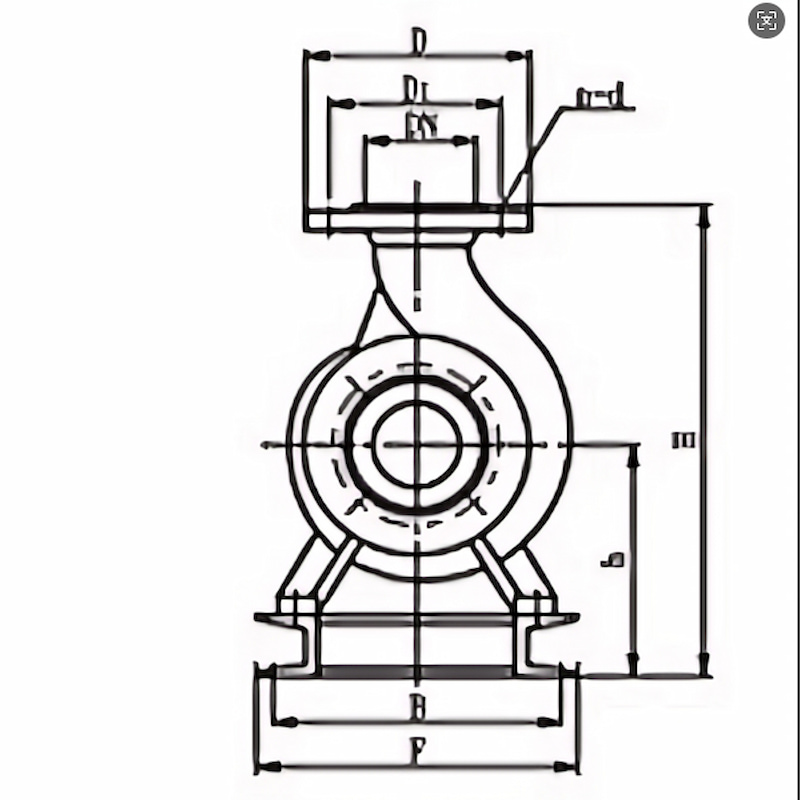

5. Distinctive structure. Pump body fitted with water drain hole at the underside, inlet and outlet flanges fitted with pressure tapping, thus to ensure normal operation and maintenance.

6. This series of pumps have horizontal inlets and vertically upward outlets for the convenience of pipeline arrangement.

Working Conditions

1.The maximum working pressure of pump system is 1.6MPa.namely pump suction pressure + pump delivery head ≤1.6Mpa.(To acquire working pressure of pump system greater than 1.6MPa should be specified separately when placing an order for our convenience to use cast steel for wetted parts and connection partsin production).

2. The medium to be handled shall be clean water or other liquids similar to water in physical and chemical properties. (To handle medium carrying small particles, please specify when placing an order for our convenience to use wear resistant mechanical seal).

3. Ambient temperature not exceeding 40℃, height above sealevel not exceeding 1.000m, and relative humidity not exceeding95%.