Model :

100LSP10-4*10Rated flow (m³/h) :

10Rated head (m) :

40Motor speed (rpm) :

2940Motor power (kw) :

5.5Material :

cast ironLong Shaft Deep Well Pump

Flow Rate: 2L/S ~ 350L/S

Maximum Rated Pressure: 2.0 MPa

Medium Temperature: ≤80℃

Water Quality: Neutral (pH=6.5~8.5), Chloride Content ≤400mg/L

Adopts advanced hydraulic and structural designs, combined with new technologies such as Ashland industrial epoxy coating on the blade flow paths, ensuring excellent performance and long service life through rational material selection.

Features a sand-throwing ring device and labyrinth structure to prevent sand particles from entering the bearings.

Both impeller and motor shafts are supported by copper bearings, with radial runout controlled within 0.13mm (US standard), ensuring stable operation and low noise.

The pump base features an aesthetically pleasing design with large access windows for easy maintenance and packing replacement.

Constructed from ductile iron and various stainless steel grades (2Cr13, 304, 316) to meet diverse operating conditions and technical requirements.

Introduction of long shaft deep well pump

LSP Type series long shaft deep pump adopts advanced hydraulic model and structure design, adopts Ashland resin process core, blade channel epoxy coating and other new processes; the pump has high efficiency, the performance curve has no hump. The pump uses sand throwing device, and the maze structure makes the sand particles unable to enter the bearing. The radial beating control of the impeller shaft, drive shaft and motor shaft is controlled within the American standard 0.13mm, and the pump runs smoothly and has low noise. The pump seat is beautiful in shape and large in window, which is easy to repair and replace the filler.

Scope of application of long-shaft deep well pump

LSP Type long shaft deep well pump is widely used in water plants, hydropower stations (maintenance, leakage and drainage pumps, etc.), thermal power plants (industrial, living, fire pump, etc.), steel plants (circulation cooling, living, iron pit pump, etc.), agricultural irrigation, fire, municipal and other industries.

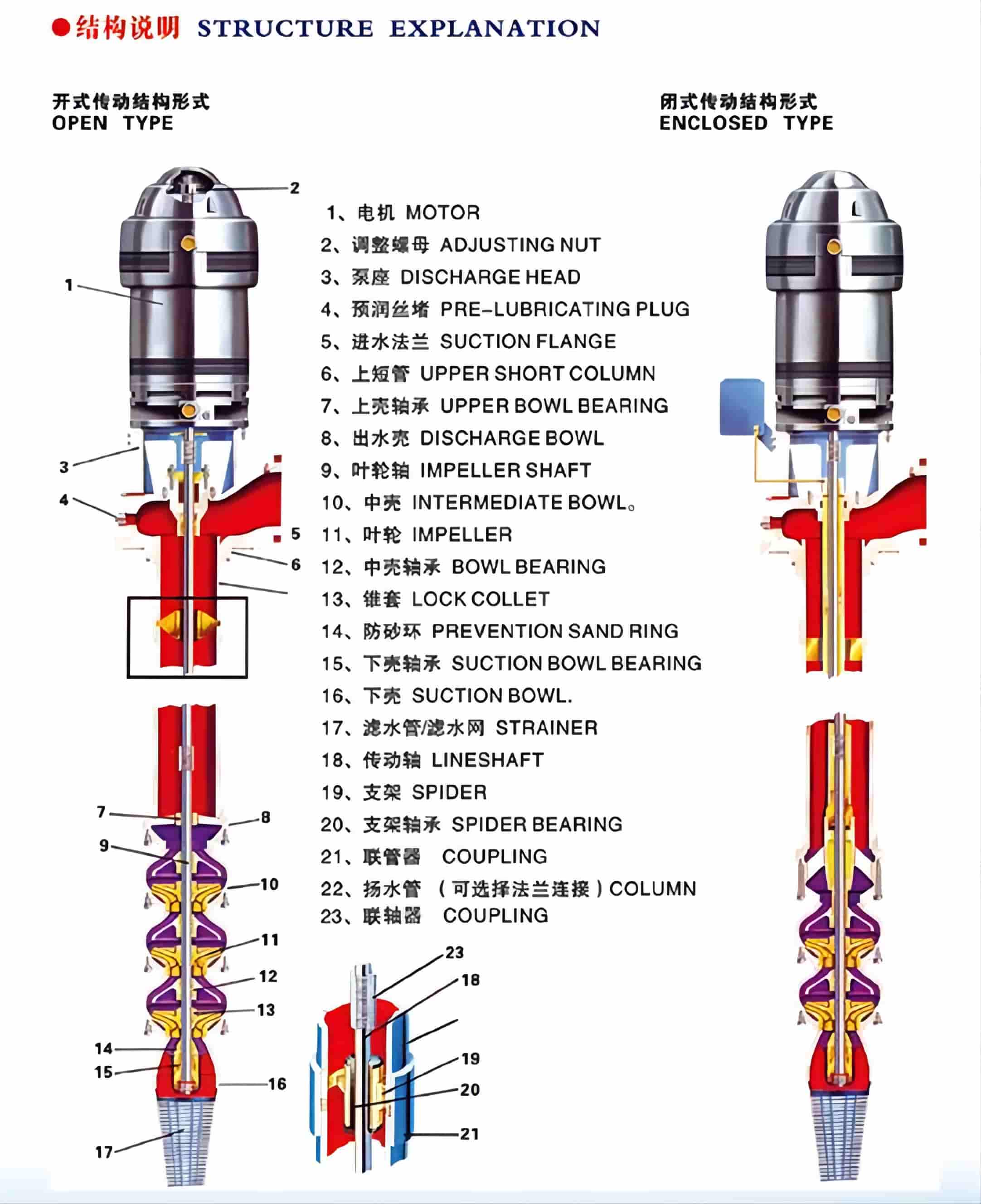

Internal structure of long shaft deep well pump

1.Motor: deep shaft motor (YLB), or solid shaft ordinary vertical motor;

2.Adjust the nut: adjust the impeller axial series quantity;

3.Pump seat: bear heavy load, and convenient installation of packing box;

4.Pre-lubricating wire plugging: before starting, inject clean water through the place to lubricate the internal bearings of the pump;

5. Upper short pipe (short pipe B): connected with a flange, the upper flange of the short pipe is connected with the pump seat, and the lower flange is connected with the main pipe flange;

6.Impeller shaft: 2 Cr 13 stainless steel or 45 # high quality carbon steel (chrome plating);

7.Medium shell: smooth flow path, reduce friction resistance, and improve efficiency. Materials are: HT 200, QT 450,2 Cr 13,304,316, etc.;

8.Impeller: cooperate with the middle shell design, efficient, wide working range, and precise calibration balance to ensure smooth operation. Materials: HT 200, Silicone brass, QT 450,2 Cr 13,304,316, etc.;

9.Medium shell bearings: copper bearings, wear-resistant rubber bearings or imported polymer bearings. Reliable work, long life.

10.Cone sleeve: fix the impeller on the impeller shaft.

11.Lower shell bearing: copper bearing, grease filling, long-term fault-free operation.

12.Lower shell: lead the liquid in the water network evenly to the impeller with minimum loss. Materials are: HT 200, QT 450,2 Cr 13,304,316, etc.;

13.Filter network: the length of the filter network should be appropriate to reach a good state, and can prevent large particle objects from entering the pump;

14.Drive shaft: high-strength carbon steel, chrome-plated surface of the bearing position. According to the need, can provide stainless steel material;

15.Lift pipe: water pipe can be installed by threaded connection or flange connection.