Low maintenance, no leakage, safe and reliable commonly used pump, effectively isolate high corrosive dangerous chemical medicine, not only make the operator away from the threat of chemical medicine, but also to fulfill the obligation to protect the environment.

Model :

QSP-30RM-PVR15Imported caliber (DN) :

20Export caliber (DN) :

20Rated flow (m³/h) :

1.92Rated head (m) :

3.8Motor power (kw) :

0.045Material :

GF+PPFOB Price (USD$) :

105Plastic Magnetic Drive Pump

Technical parameter:

Flow , Q: maximum 1210L/min

Head, H: maximum 35m

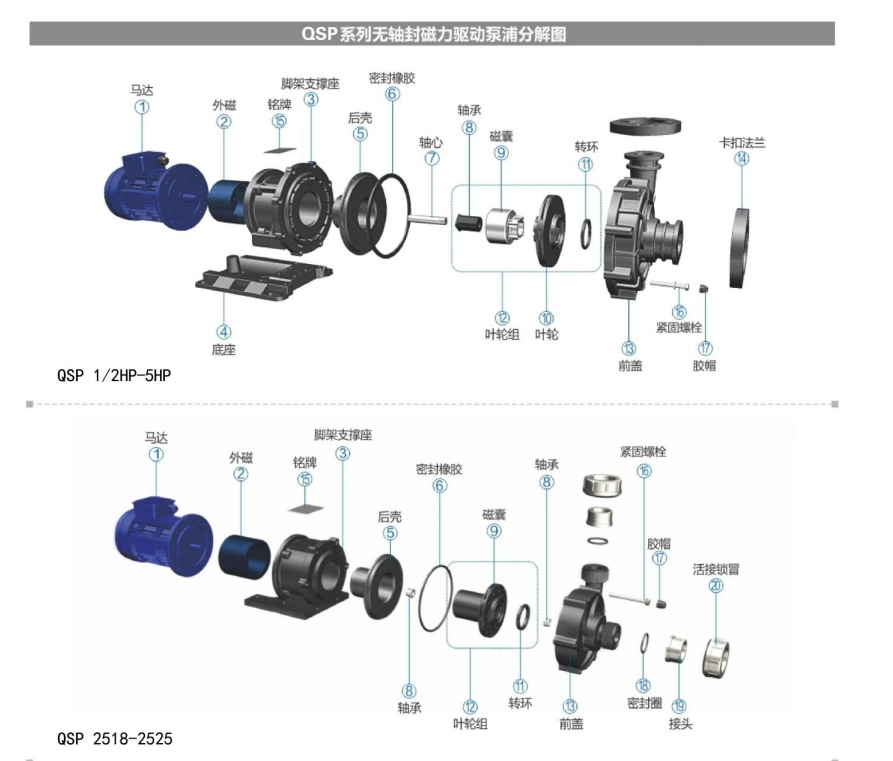

Non-contact construction

By accurately setting the relative position of the passive magnet and the active magnet, the position of the magnetic sac can be effectively controlled, even if the rear end of the bearing does not contact with the rear thrust ring when idling. This structure effectively inhibits the generation of friction heat and ensures the lubrication of the friction part.

The structure is strong and highly efficient

In the pump front shell and back shell and other stress concentration parts, all the use of reinforcement reinforcement, further improve the pressure resistance and mechanical strength of the pump.

In previous bearing with the composite with fixed way, and the axial reversion fixed structure, the bearing limit to the bottom of the capsule and the bottom of the impeller, the forming design of the impeller, ensure the operation of high efficiency and mute, not easy to damage, improve the reliability of the pump under the condition of high temperature conditions.

Innovative design, with no leakage

The pump front cover is a new design, with the buckle type, the front cover entrance flange integrated molding, to prevent leakage. There are also reinforced sealing gasket design to extend the service life. Traditional flange type with thread, hot melt seal, in high temperature and high pressure environment is easy to leak, rubber is easy to aging.

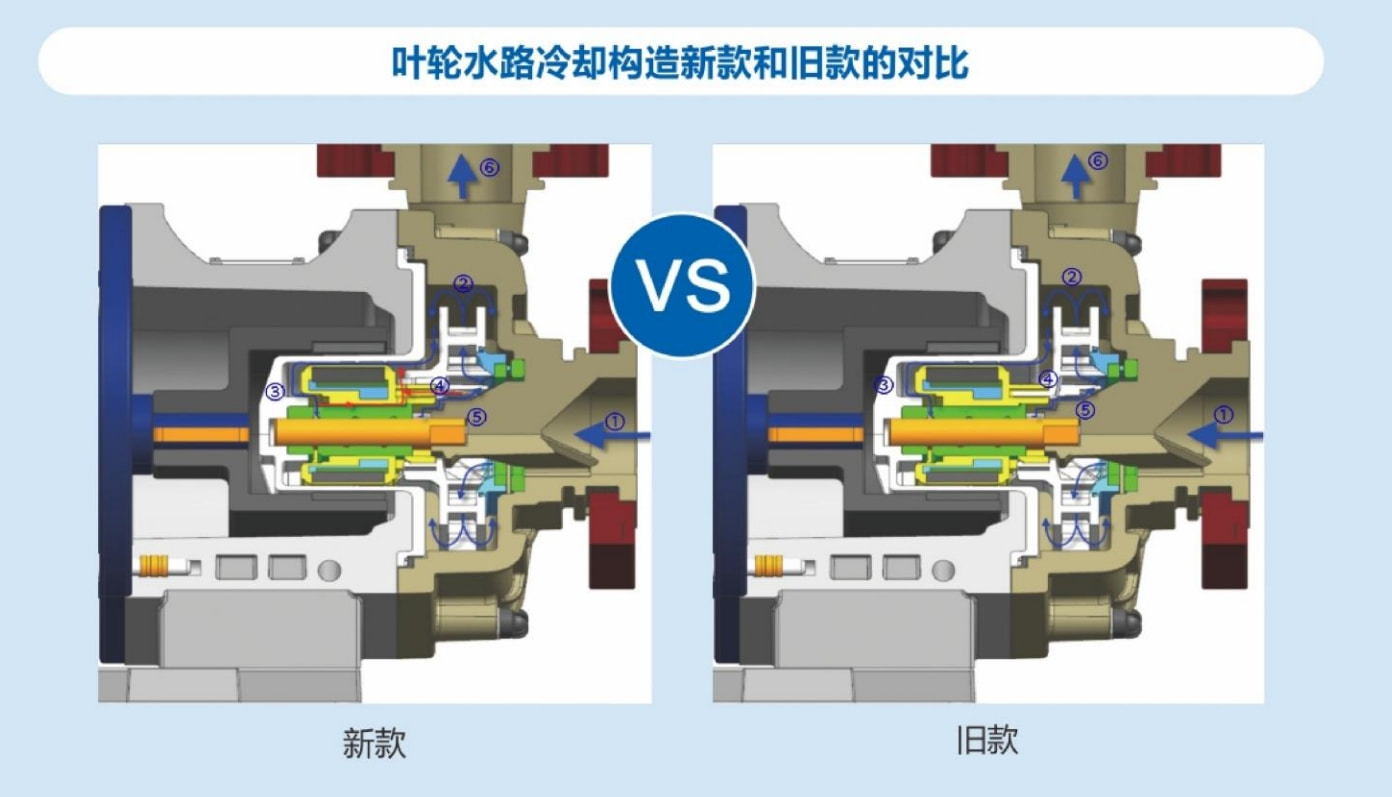

New and upgraded self-circulating cooling structure

In the impeller and the magnet connection fixed with heat diffusion hole, also in the shaft and the magnet joint open heat vent hole, the hole can make the pump shaft and the bearing around the liquid under centrifugal force and backwater blade forced circulation, fast and effective distribution of heat generated by friction, prevent the pump chamber fat material caused by high temperature deformation and melting.