KSB provides a wide range of products for food and beverage production

KSB products for food and beverage production always guarantee the highest quality, comply with hygiene standards and absolute process reliability.

Food and beverage industry: a demanding industry

The food and beverage industry must adhere to stringent hygiene standards. Equipment and components must consistently deliver reliable production with consistent quality. This requires high-performance pumps that ensure process reliability, prevent downtime, and operate with energy efficiency. Only through such measures can manufacturers reap the benefits of cost-effective process improvements.

Everything you need: KSB is your trusted all-in-one service provider

As a full-service provider in the food and beverage industry, KSB specializes in both hygiene products and secondary processes. Beyond pumps and valves for peripheral equipment, KSB offers a comprehensive range of hygiene solutions.

From brewing processes and animal feed production to infant formula, pasta, and other food items, as well as complex sugar manufacturing, KSB's high-performance food pumps and valves are utilized across diverse industries. These systems consistently deliver exceptional quality and absolute process reliability while meeting stringent hygiene standards, effectively minimizing unplanned downtime.

The KSB pump operates at peak efficiency across all application scenarios.

KSB has a dedicated "LSA Team" (Life Science Applications) to address your challenges. This team is specially trained and possesses extensive applied technical expertise to meet the requirements of the food and beverage industry.

Warm pumping, no flaws: KSB products are hygienic, of superior quality and convincing

As a full-service provider, KSB offers pumps and valves that meet all hygienic process requirements for food and beverage production. These products are ideal for various production processes in the food and beverage industry.

Beer production is a prime example: KSB provides optimal pumps for any conveying task in brewing, auxiliary, and cleaning processes. KSB products are used in brewery water treatment, fermentation rooms, filtration chambers, filling equipment, and CIP/SIP cleaning.

The food pump is designed in compliance with the EHEDG Hygienic Design Directive and EG 1935/2004. Whether for pumping, metering, or filling, the design with minimal dead space not only ensures a longer shelf life for the final product but also optimizes the cleaning process.

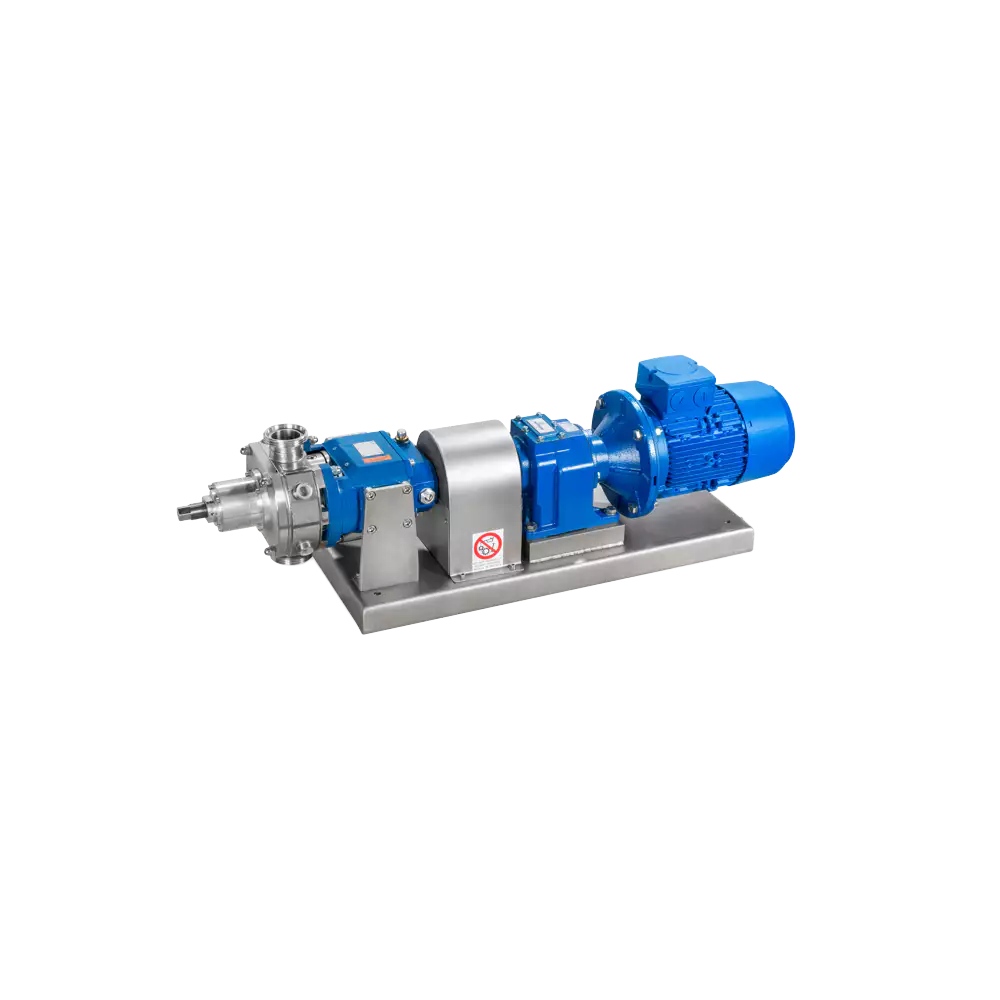

KSB's food pumps are constructed from hygienically flawless materials that can withstand CIP/SIP cleaning. They handle, pump, and meter high-viscosity liquids like syrups with exceptional gentleness, thus meeting stringent quality standards.

Wherever sugar is produced, Etanorm excels in addressing challenges. The KSB pump is seamlessly integrated into the production processes of one of the world's largest sugar mills. Eta standard pumps and KWP series slurry pumps are utilized not only in beet processing but also in all sugar production stages from sugarcane to starch. Vita series sanitary pumps are employed in downstream processes, serving as critical auxiliary components across multiple stages including juice extraction, purification, concentration, and crystallization.

KSB's technical expertise is built on years of experience and sustained R&D investments, which have driven continuous improvements.

KSB provides a wide range of products for food and beverage production:

sanitary pump

in-line pump

Standard pump/Direct-connected pump

Hot water pump/heat transfer oil pump

Chemical standard pump

positive displacement pump

Advantages :

Comply with health standards

High process and operational reliability with no downtime

Reliable production, consistent quality

The product is durable and easy to maintain, enabling cost-effective manufacturing processes.

Save costs through energy-saving processes

Pumps for sanitary areas and peripheral equipment

Application Area :

Beverage production (e.g. beer, wine, mineral water, soft drinks, spirits)

Food production (e.g. yeast, yogurt, milk, whey, cream, sugar, chocolate, honey, ice cream, meat sauce, jam, gelatin, edible oil)