Chemical Pump Benchmark|KSB MegaCPK

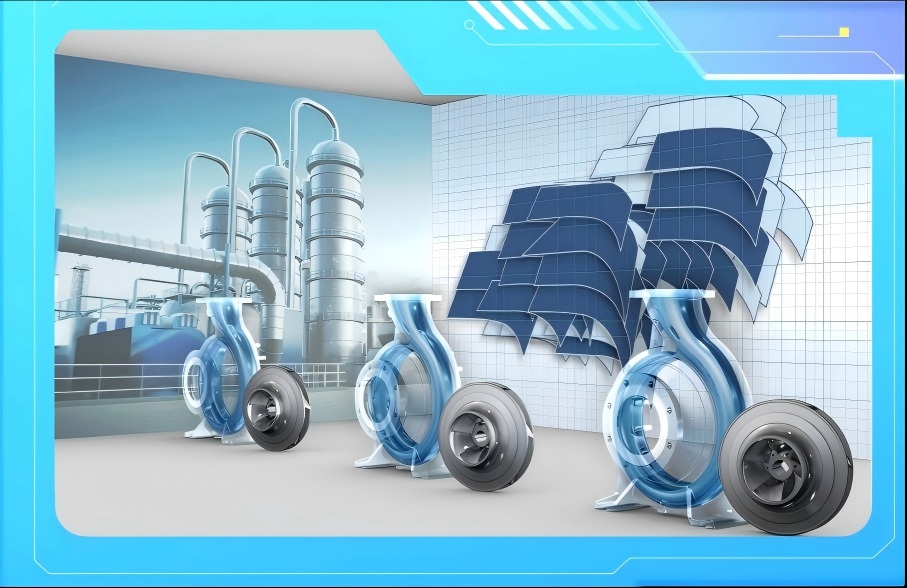

In the chemical industry, a pump's performance often determines the stability of the entire production system. To meet the stringent demands for safe, efficient, and reliable fluid transportation in petrochemical and chemical sectors, the KSB MegaCPK series chemical pumps were developed, redefining the benchmark for industry-standard chemical pumps.

As a milestone in KSB's core product line and standard chemical pump products in the petrochemical and chemical industry, the MegaCPK not only strictly adheres to the ISO2858/ISO5199 international standards in design and manufacturing, but also stands out with its outstanding energy efficiency, flexible configuration, and exceptional reliability, making it the ideal choice for fluid handling in industrial applications. From the integrated base in Zhanjiang, China to the Belo Monte Hydropower Station in Brazil, South America, the MegaCPK is quietly supporting the stable operation of major global industrial projects as an "invisible champion," empowering industrial development.

Meet extreme challenges and demonstrate superior quality

The MegaCPK pump demonstrates exceptional versatility across diverse industries including petrochemicals, chemical processing, high-voltage power transmission, brine treatment, hot water systems, process engineering, and seawater desalination. Particularly adept at handling complex chemical media, it ensures long-term safe and stable operation for both highly corrosive organic solvents and high-concentration inorganic acid solutions, providing reliable fluid handling support for industrial production.

The excellence of the MegaCPK pump stems from its sophisticated design and manufacturing craftsmanship:

|

parameter |

numeric value |

|

rate of flow Q |

Up to 2,700 m³/h (50Hz) and 3,300 m³/h (60Hz) |

|

head of delivery H |

Up to 162m (50Hz) and 233m (60Hz) |

|

running temperature t |

-40°C to +400°C |

|

operating pressure p |

Up to 40bar |

Premium materials to meet diverse needs

MegaCPK offers a wide range of materials to meet the needs of various media and operating conditions:

● Common materials:

Gray cast iron (JL1040/A48CL35)

Cast steel (GP240GH+N/A216GrWCB)

Stainless steel (1.4408/A743Gr CF8M)

● Special materials:

Biphasic steel (1.4593/1.4517/A995GrCD4MCuN)

super duplex steel

(1.4573/1.4469.09/A995 Gr.5A)

and other special materials, which can be customized according to specific applications.

Hardcore Power, Redefining the Performance Boundary of Chemical Pump

While conventional chemical pumps still grapple with the trade-off between efficiency and cost, MegaCPK has set a new benchmark through three core technological breakthroughs:

● Multi-Optimization·Energy Efficiency Leap: Featuring advanced hydraulic model design, it enhances efficiency while optimizing cavitation protection performance, reducing operating costs. Additionally, the wide range of pump models enables users to select smaller specifications, further lowering investment costs.

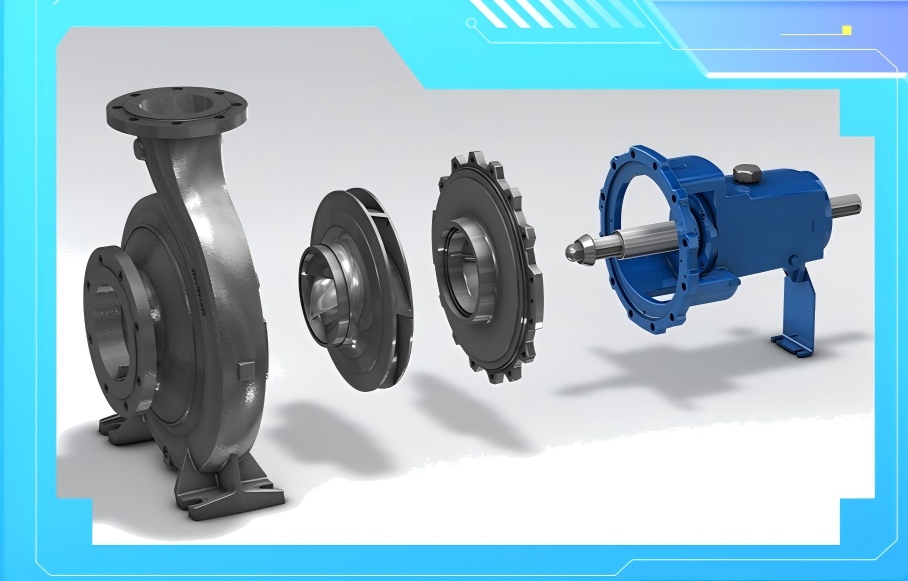

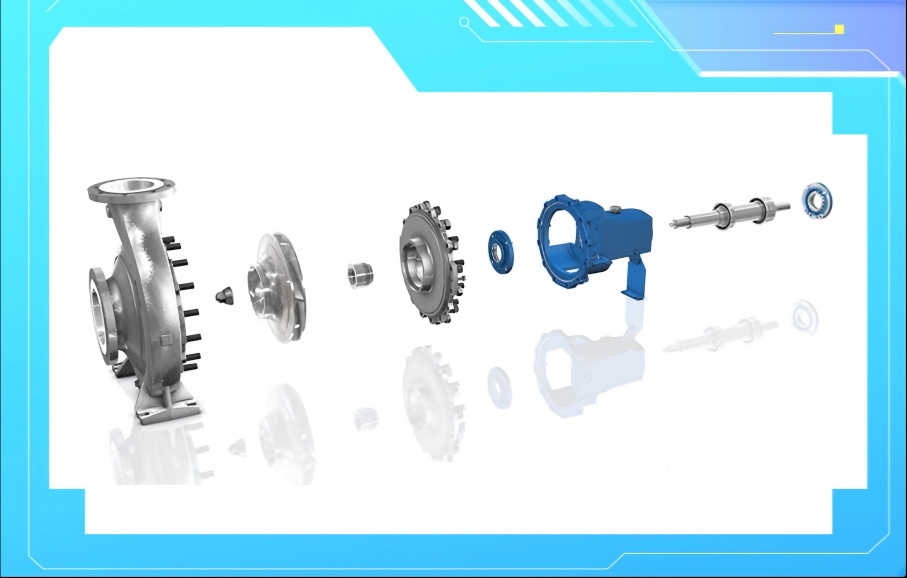

● Modular Reconfiguration & Flexible Adaptation: MegaCPK's modular design philosophy delivers exceptional flexibility.

Key components including the volute, pump cover, and impeller are available in multiple material options to accommodate various fluid media.

|

description |

G |

E |

C |

D¹) |

|

volute |

CI |

CS |

SS316 |

Duplex |

|

pump bonnet |

CI |

CS |

SS316 |

Duplex |

|

impeller |

CI |

- |

SS316 |

Duplex |

|

axle |

- |

- |

St²) |

- |

|

bearing bracket |

- |

- |

CI |

- |

|

stabilizer blade |

- |

- |

St |

- |

|

airlock cover |

- |

CrNiMoSt |

- |

Duplex |

|

pump body sealing ring |

CI |

- |

- |

- |

|

bearing sleeve (mechanical seal) |

CrNiMoSt |

St |

CrNiMoSt |

Duplex |

|

bearing bushing (packing seal) |

CrNiMoSt |

St |

CrNiMoSt |

Duplex |

|

impeller nut |

- |

CrNiMoSt |

- |

Duplex |

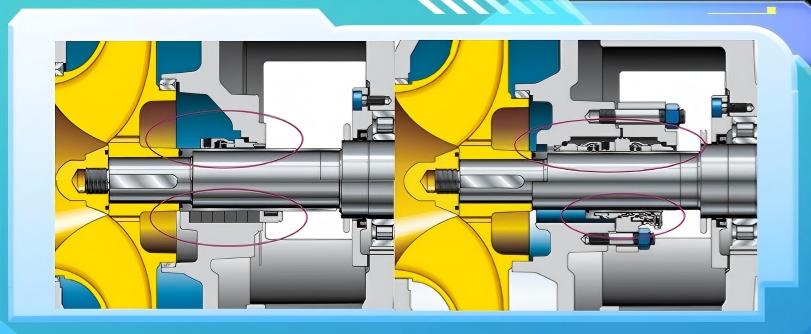

Multiple sealing configurations (packing seals, non-containerized mechanical seals, containerized mechanical seals) and bearing configurations (medium-load, economical) are available, delivering tailored solutions for diverse operational scenarios.

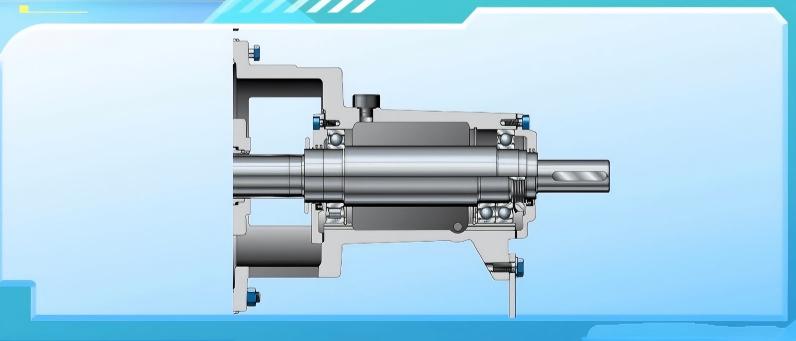

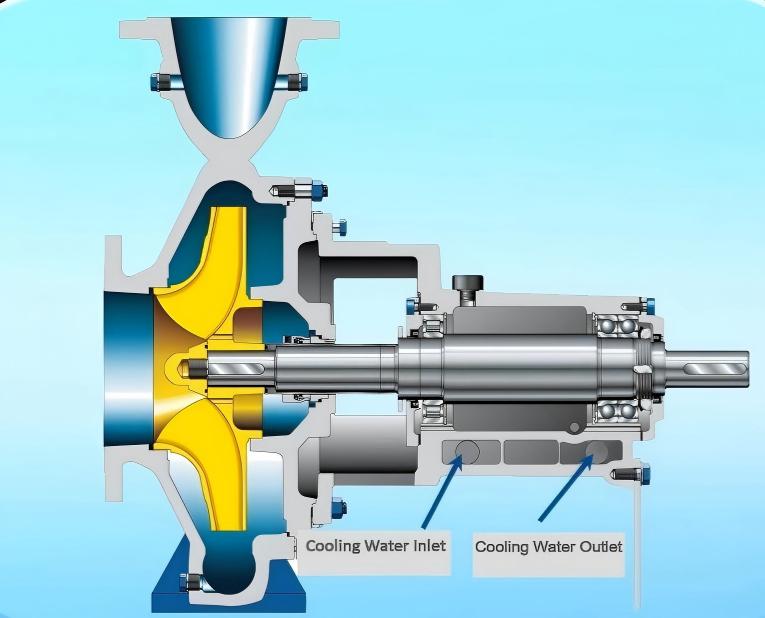

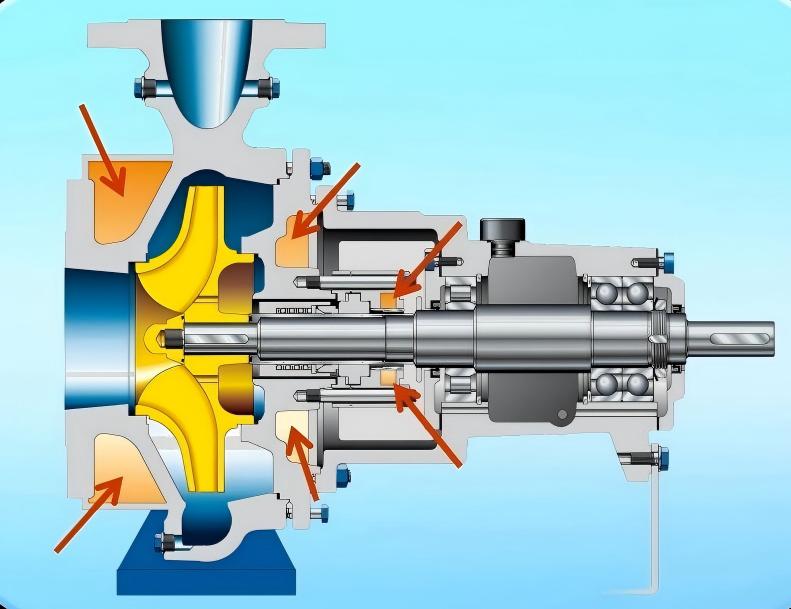

● Precision Craftsmanship · Unshakable Stability:

With reliable operation as its core design philosophy, MCPK's rear-pull structure ensures easy maintenance.

-Complies with the European ATEX directive, ensuring reliable operation under extremely high safety standards;

The cooling-equipped bearing bracket can withstand fluid temperatures exceeding 200°C.

-The heating design is suitable for conveying easily solidifiable fluids;

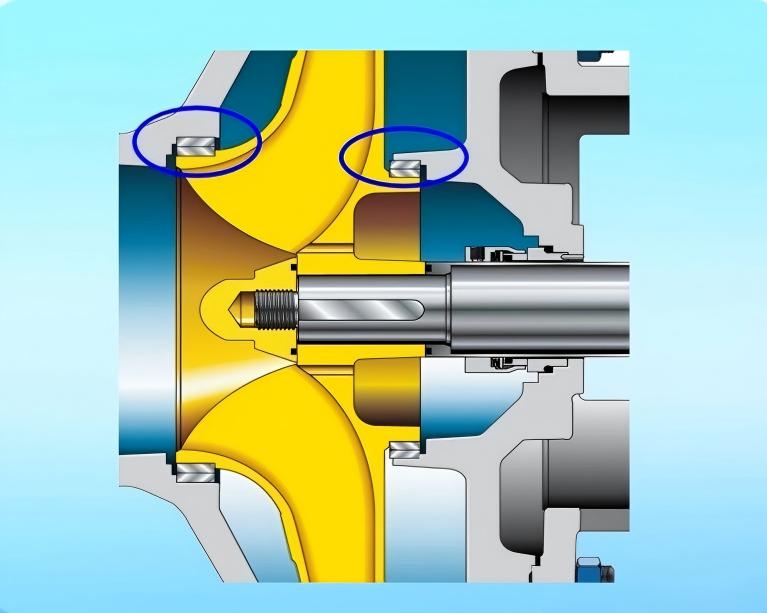

-Replaceable pump body wear rings and impeller wear rings significantly reduce customer maintenance costs;

-Achieves minimal axial thrust through clearance balancing, thereby extending bearing life;

-Low cavitation margin ensures stable operation of the pump set.

Scene Breakthrough: From Laboratory to Super Engineering

In extreme-condition test environments, the KSB MegaCPK pump has consistently outperformed in multiple key projects, setting new benchmarks with its exceptional performance.

● Chemical industry:

The Zhanjiang Integrated Base, renowned for its high standards, extensively employs KSB MegaCPK and CPKN pump units, showcasing their outstanding performance in the chemical industry.

● High-voltage power transmission and distribution sector:

The Belo Monte Project in Brazil: Awarded the 6th China Industrial Award, this project is the first overseas project of a China enterprise to win the China Industrial Award. KSB provided 8 MCPK250-200-500 CC and 8 MCPK250-200-400CC pumps for the project.

The Wudongde Project, the world's first ultra-high voltage (UHV) multi-terminal hybrid DC transmission system, employs MegaCPK or CPKN pump models at key stations including Longmenji, Liubei, and Kunbei, ensuring reliable operation and stability.

"Hidden Champion" KSB MegaCPK Your Reliable Partner

The KSB MegaCPK series chemical pumps are now making waves worldwide in chemical plants, thanks to their outstanding performance, flexible configurations, and reliable operation.

For engineers pursuing absolute reliability, choosing MegaCPK means more than just selecting a pump—it signifies embracing KSB, a 150-year legacy of industrial expertise. You'll gain access to world-leading pump and valve technologies, customized solutions, and our comprehensive premium services, all designed to safeguard your industrial advancement.