Compared with similar domestic products, BQS series mining explosion-proof sewage and sand discharge submersible electric pumps have the advantages of safety and reliability, lightness and practicality, good sewage and sand discharge performance, long service life, reasonable model spectrum, and easy selection.

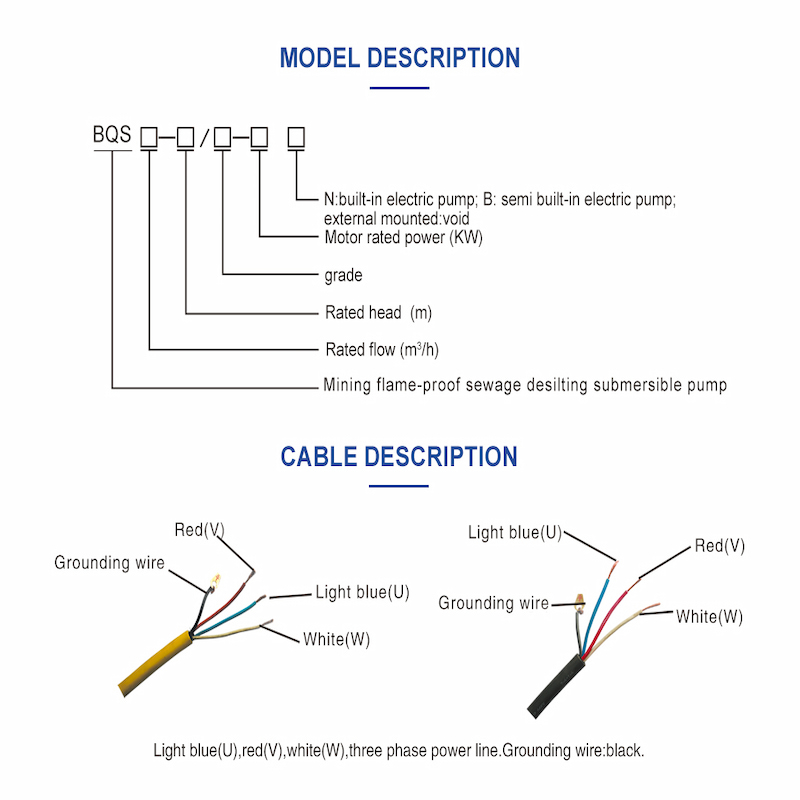

Model :

BQS10-23-1.5Imported caliber (DN) :

50Export caliber (DN) :

50Rated flow (m³/h) :

10Rated head (m) :

23Motor speed (rpm) :

3000Motor power (kw) :

1.5Material :

QT600-3 nodular cast ironBQ series Mining explosion-proof submersible drainage pump

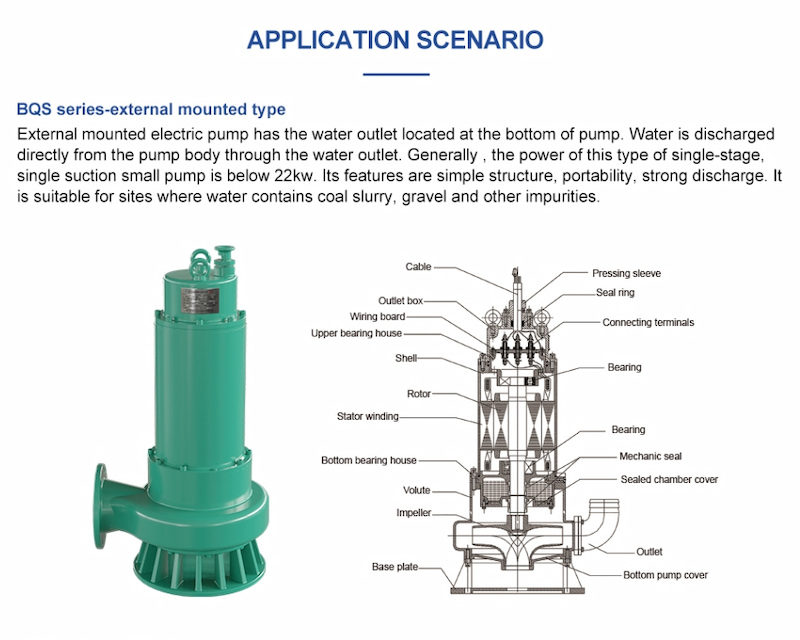

Product Introduction

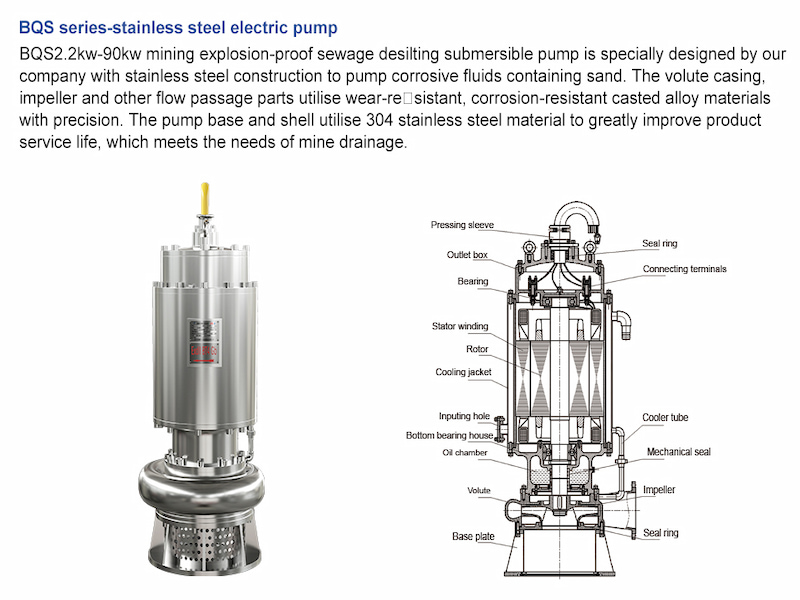

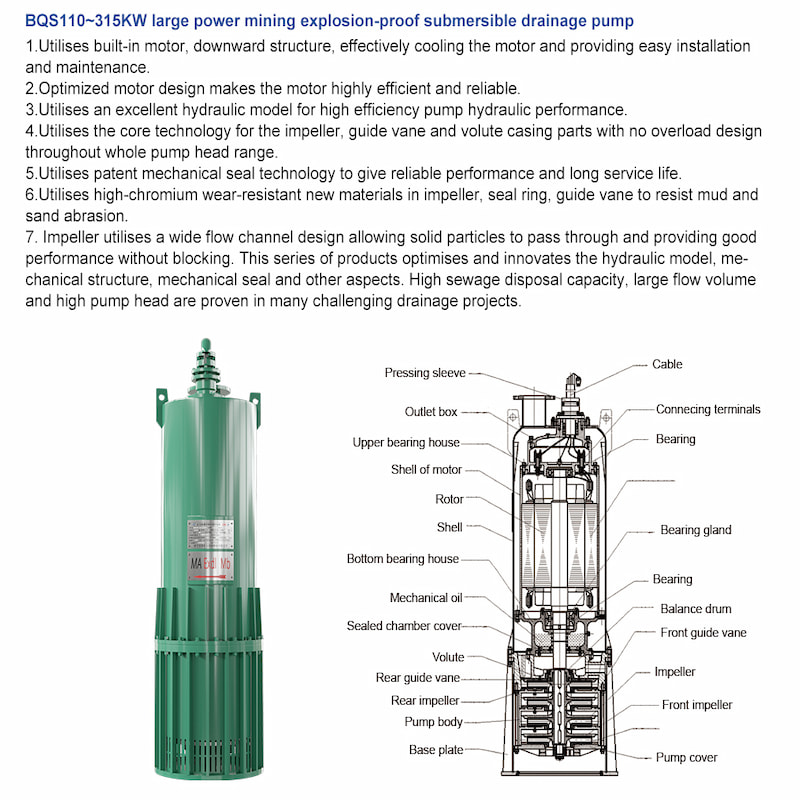

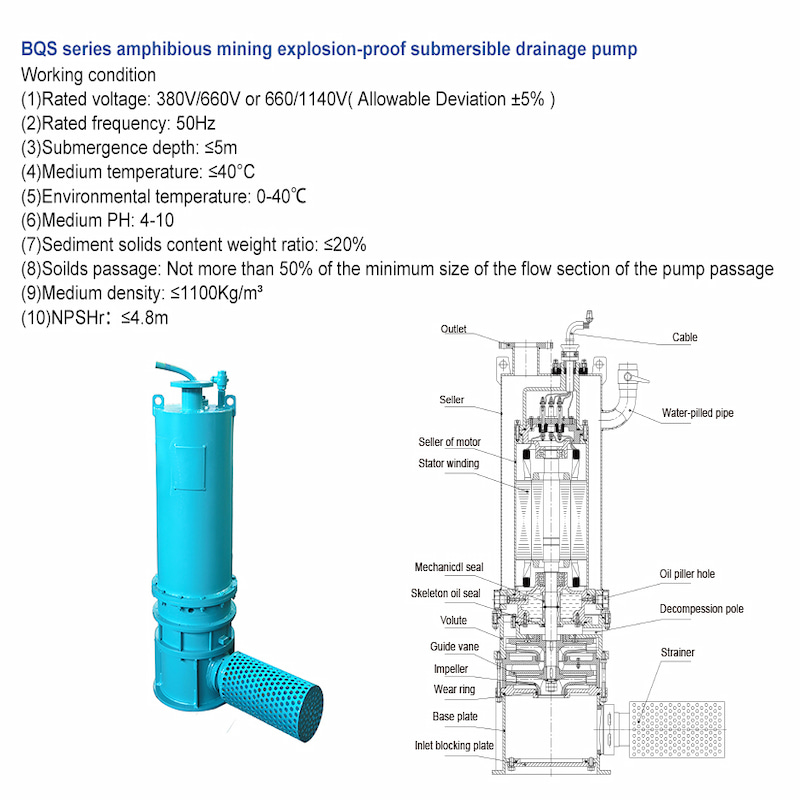

The BQS series of explosion-proof submersible electric pumps for mining sewage and sand removal offer a comprehensive range of specifications, with power ranging from 2.2kW to 315kW, flow rates from 10m/h to 2500m/h, and lifts from 7m to 700m. All products offer full lift and zero overload. The company's relentless technological innovation has addressed key technical challenges in sewage and sand removal submersible electric pumps, including product structure, parameter optimization, manufacturing processes, operating efficiency, sealing and leak prevention, and material application. The company holds over 20 patents and utilizes the latest research findings to develop a mature motor and pump manufacturing process. Compared to similar domestic products, these pumps offer advantages such as safety, reliability, portability, practicality, excellent sewage and sand removal performance, long service life, a comprehensive product portfolio, and easy selection.

Main Applications

These pumps are suitable for use in underground coal mines where methane (commonly known as gas) and coal dust explosion hazards exist. They are used to transport mixed wastewater containing insoluble solids such as mud, sand, coal slime, coal stone, coal slag, and fibrous matter. It is also suitable for discharging wastewater, rainwater, and sewage containing solid particles and long fibers in buildings, hospitals, residential areas, municipal engineering projects, road traffic and construction, factory sewage treatment, and small-scale sewage treatment.

Environmental Requirements

1. Power supply: 380V, 660V, or 1140V three-phase, 50Hz.

2. Medium temperature generally not exceeding 40°C, pH 5-9, and medium density ≤11kN/m³.

3. Submersible depth not exceeding 5 meters based on the impeller center.

4. Special designs are available upon request to accommodate highly corrosive fluids.

5. The diameter of solids in the medium must comply with MT/T671-2005. Please indicate any special requirements when ordering.

6. MT818.5-2009 flame-retardant cable for coal mines is used.

Features

1. Model Selection: Optimized performance, smooth and clog-free operation, and strong sewage and sand removal capabilities. The pump has a zero-overload (full head) characteristic, meaning the input power does not exceed the power of the matching motor at any operating point. Suitable for various applications in coal mines, a single machine can be used for multiple purposes.

2. Mechanical Seal Improvement: Utilizes independent tandem mechanical seals and double-end mechanical seals.

3. Structural Optimization: The structural design enhances mechanical seal sealing, smooth operation, and increased reliability. The optimized design is lighter, more practical, and has low energy consumption, allowing for long-term dry operation in dry conditions.

4. With an IPx8 motor protection rating, the submersible motor offers excellent cooling, lower temperature rise than conventional motors, and improved durability. Class F insulation extends the motor's service life.