The differences between self-priming pumps and centrifugal pumps are mainly reflected in the following aspects:

1. Working Principle:

Self-priming pumps: Before starting the pump, the pump casing is filled with water (or water itself is present in the pump casing). After starting, the impeller rotates at high speed, causing water in the impeller grooves to flow toward the volute. This creates a vacuum at the inlet, opening the water inlet check valve. Air in the suction pipe enters the pump and flows through the impeller grooves to the outer edge.

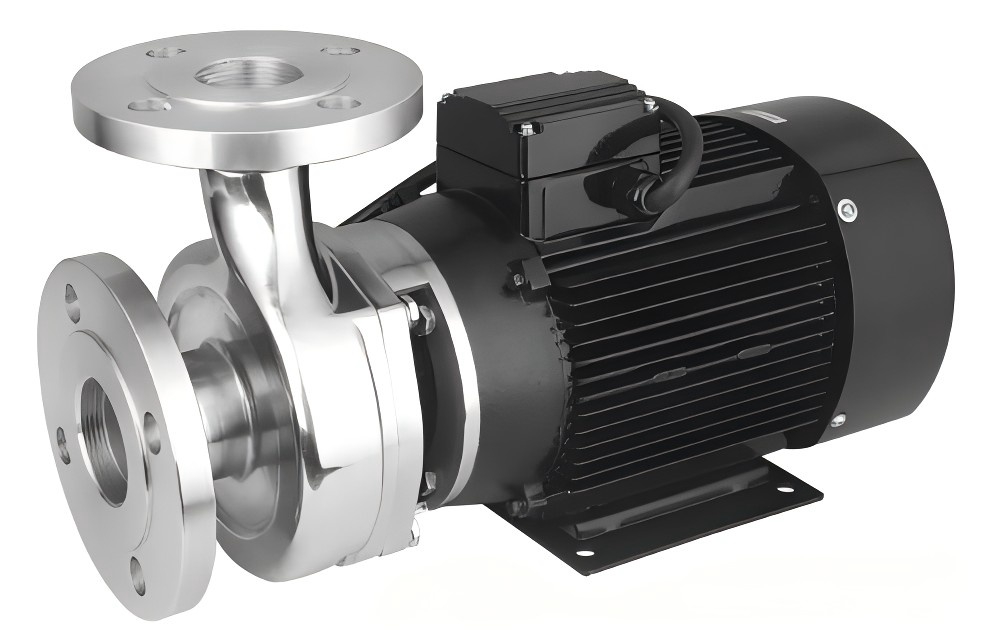

Centrifugal pumps: These pumps operate by centrifugal motion of water caused by the rotation of the impeller. Before starting the pump, the pump casing and suction pipe must be filled with water. Then, the motor is started, causing the pump shaft to rotate the impeller and water at high speed. This centrifugal motion causes the water to be thrown toward the outer edge of the impeller and flow through the flow channel of the volute casing into the pump's pressure water line.

2. Applications:

Centrifugal pumps: Used in liquid transportation, cooling systems, industrial cleaning systems, aquaculture, fertilization systems, metering systems, and industrial equipment. They are also widely used in industries such as power, metallurgy, coal, and building materials to transport slurries containing solid particles.

Self-priming pumps: They disperse water into fine droplets for spraying, making them ideal for farms, nurseries, orchards, and vegetable gardens. They are suitable for handling clean water, seawater, chemical media with acidic or alkaline content, and generally pasty slurries. They can be used with filter presses of any model and specification, making them an ideal companion pump for filtering slurries while feeding them.

3. Components:

Centrifugal pumps: Consists of six components: impeller, pump body, pump shaft, bearings, sealing rings, and stuffing box.

Self-priming pumps: Consists of a suction chamber, liquid storage chamber, scroll chamber, liquid return port, and gas-liquid separation chamber.

4. Starting Method:

Centrifugal pumps: To start, both the inlet pipe and the pump body must be filled with water, or an auxiliary device must be used to evacuate the inlet pipe.

Self-priming pumps: To start, a certain amount of starting circulating water must be injected into the pump body.

5. Different Devices:

Centrifugal Pumps: Must be equipped with a foot valve at the bottom of the inlet pipe or an air extraction device at the outlet.

Self-Priming Pumps: Only a filter is installed at the bottom of the inlet pipe, without a foot valve.

6. Advantages:

Centrifugal Pumps: Compact structure, wide flow and head range, suitable for mildly corrosive liquids, uniform flow, smooth operation, low vibration, no need for special shock-absorbing foundations or equipment installation, and low maintenance costs.

Self-Priming Pumps: Compact structure, easy operation, stable operation, easy maintenance, high efficiency, long service life, and strong self-priming capacity.

7. Characteristic Curve:

Centrifugal pump: The characteristic curve will not show the abnormal phenomenon of the self-priming pump mentioned above, and the efficiency is relatively high.

Self-priming pumps: The characteristic curve is generally flatter than that of centrifugal pumps, meaning that the flow rate changes less for the same head change. With strong self-priming capacity, they can be started with no fluid in the suction pipe. However, when the flow rate is low, the characteristic curve of a self-priming pump will exhibit anomalies, meaning that the head increases as the flow rate decreases, resulting in generally lower efficiency.