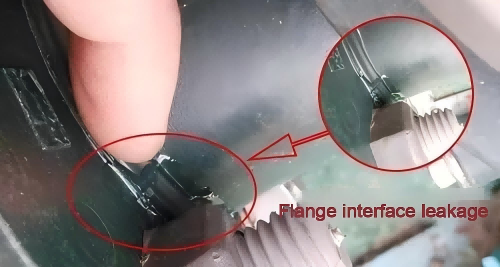

Flange interface leakage

Cause: This is typically caused by excessive strain on the fastening screws.

Solution: Tighten the screws diagonally, not all at once. Ideally, the gasket between the two flanges should be the same size as the flanges.

The motor is running but no water is being pumped out.

Check the motor's direction of rotation

Cause: The motor may be running in the wrong direction, or there may be air leaks at the inlet.

Solution: Check the motor's direction of rotation and check for air leaks at the inlet.

Mechanical seal leakage

The mechanical seal is burned due to dry pumping without water

Possible cause for new pumps: Dry running without water may damage the shaft seal. For older pumps, there are several possible causes:

1. Wear on the dynamic and static seal surfaces

Cause 1: Overtightening. Observe the dynamic and static seal surfaces. If there is severe burning, blackening, or deep marks, or if the sealing rubber has hardened and lost its elasticity, this is due to overtightening.

Cause 2: Too loose installation. Observe the surfaces of the dynamic and static seal rings. A thin layer of scale can be wiped off, and the surfaces are largely unworn. This is caused by a loss of spring elasticity, improper assembly, or axial movement of the motor.

Cause 3: Poor water quality containing particles. Poor water quality, containing small particles and a high hydrochloric acid content in the medium, can cause abrasive wear on the seal surfaces or strain, creating grooves and annular grooves.

Cause 4: Dry wear damage caused by water shortage. This phenomenon is often seen in bottom-valve installations with negative inlet pressure, air in the water inlet pipe, and air in the pump cavity. After the pump is started, the friction of the seal at high speed generates high temperatures, preventing cooling. Check the seal to see if the spring tension is normal, the friction surface is charred and blackened, and the rubber is hardened and cracked.

Cause 5: Cavitation. Cavitation primarily occurs in hot water pumps. Because the medium is hot water, the high water temperature generates steam. Steam in the pipes enters the high areas of the pump chamber, where it cannot be expelled. This causes water shortages, dry wear of the mechanical seal, and cavitation. An automatic exhaust valve must be installed and the mechanical seal replaced.

Cause 6: Assembly issues. The pump cover may not be installed level, causing the shaft and cover to be misaligned, resulting in misalignment of the moving and static surfaces. Short operation can lead to wear on one side and water leakage. It's also possible that the rubber components or surfaces of the moving and static rings may be damaged during installation.

2. Mechanical sealant failure

Causes of mechanical sealant failure: Aging and deformation of rubber components, primarily in hot water pumps. Symptoms of mechanical sealant failure include excessively high water temperatures, which dissolve the rubber. Visually, the rubber surface appears loose and rough, losing its elasticity, leading to failure.

3. Causes of failure in the static ring chamber of the pump cover

The primary cause is large dimensional errors in the machining of the inner bore of the static ring chamber, resulting in a rough surface. Symptoms include water spraying from the axial direction, a gap between the stationary ring and the inner bore, or a rough inner bore, causing the stationary ring to rotate with it and rubber wear.

4. Poor machining precision, undersized, rough, or rusty motor journals

The motor journal (where the rotating ring rests) may be undersized, or the pump may be corroded by corrosive media, or due to prolonged downtime, with water acting as the medium. The electrode potential difference between the steel shaft and the cast impeller and pump cover creates a galvanic reaction, leading to journal corrosion. Symptoms include spotty corrosion on the surface.