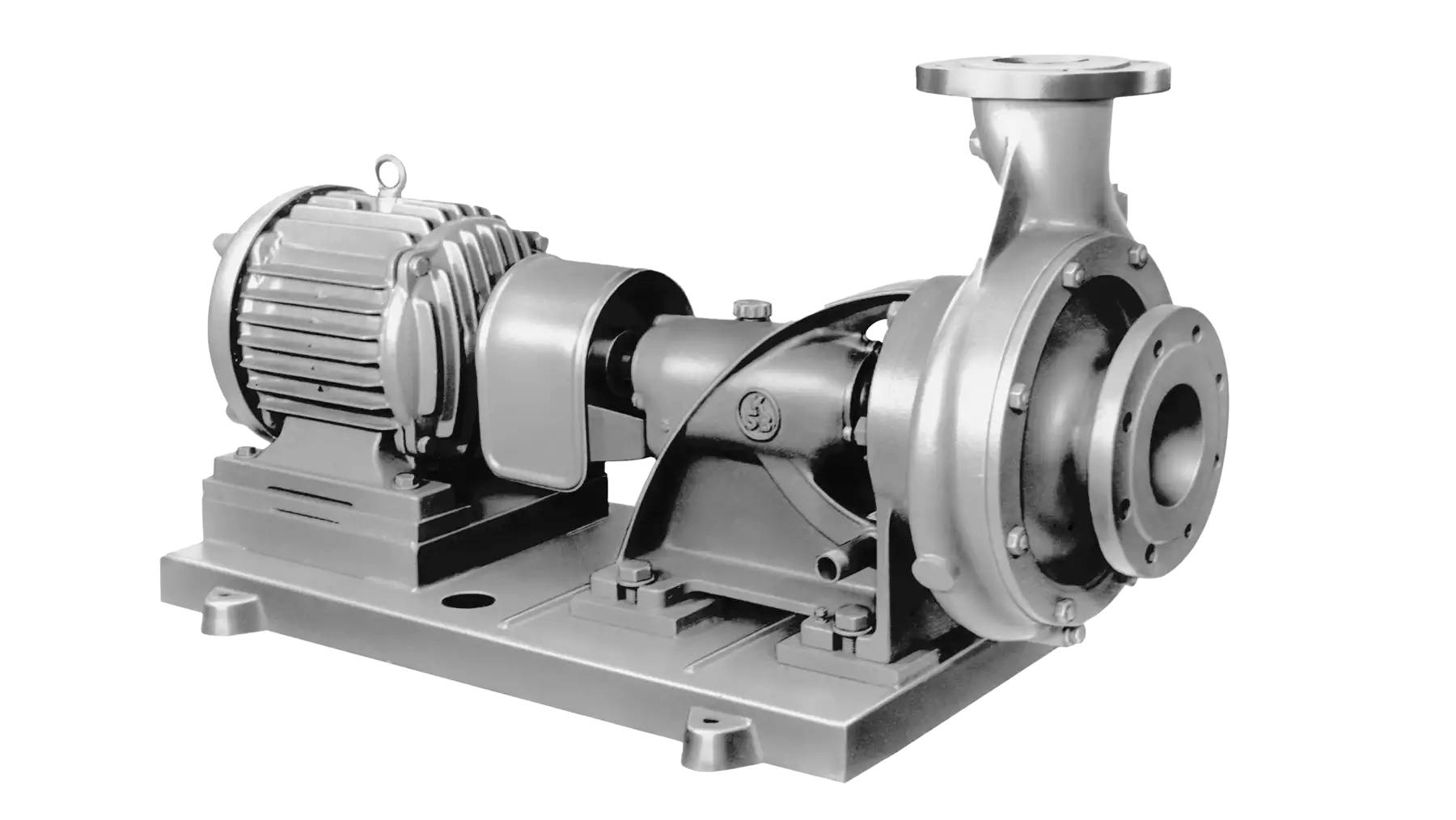

Etanorm sets the standard for all-round performance

Being a model is no easy task. Being a model means maintaining peak performance and continuous improvement, as KSB's Eta series pumps embody. The series' origins date back to 1935/36, and since its launch, over 2.7 million units have been sold worldwide, making it the most successful standardized water pump in the global market.

The Eta series' success is primarily due to its diverse range of variants and applications. The Eta portfolio includes standardized water pumps with conventional seals in a wide variety of designs, including variable-speed models and leak-free variants. The Etanorm series offers ideal solutions for a wide range of applications.

In the mid-1930s, KSB decided to explore a new path. At that time, the young Dr. Fritz Krisam, who later became Head of KSB's Design/Engineering Department, consolidated KSB's then-complex single-stage centrifugal pumps into a single, unified series. He named it after the Greek letter Eta (η), which stands for efficiency in engineering.

Etanorm:

“Norm” (derived from the English word norm, meaning “standard”) emphasizes its standardized design (compliant with EN 733) to ensure consistent performance across a wide range of applications.

This new pump series lived up to its reputation and set a benchmark for efficiency. In the early 1950s, the Eta series underwent a technological evolution, again with increased efficiency as its primary goal. The next generation, released in 1968, also maintained this focus.

In the 1970s, the selection chart for this series became the basis for new pump standards and a reference for many international manufacturers. Based on the EN 733 standard for 10 bar pumps, KSB named this successful series Etanorm—"norm" comes from the German/English word for "standard." Since then, Etanorm has become the world's best-selling standardized pump.

Eta Family History

1935

KSB launches the Eta series—energy-efficient single-stage pumps designed for industrial applications.

1968

The standardized Etanorm series is launched, combining standardization, high efficiency, and high reliability.

2017

The first Etanorm equipped with the MyFlowDrive 1 drive system is launched.

2023

The EtaLine Pro series is launched, combining extreme efficiency, unprecedented flexibility, and sustainable production.

The word "standardized" in "standardized pumps" can be somewhat misleading. In fact, the Etanorm series boasts one of the most diverse pump variants. The average order batch size for all pumps sold in this series is approximately 1.4. This wide selection of sizes and materials ensures that customers receive the pump that best suits their specific application. By tailoring the impeller to the operating point, low-wear operation is also guaranteed.

For this classic product that has already demonstrated excellence in energy consumption, reliability, and durability, the challenge facing our R&D team began with a simple question: How can we set a new benchmark again? After repeated discussions, two key factors prompted us to further innovate and optimize the technology of Etanorm.

Hydraulic Modeling is Key to Efficiency

A pump's hydraulic model is central to ensuring high efficiency and low energy consumption. The Etanorm consistently delivers outstanding performance thanks to its optimized hydraulic model. Its extensive selection chart almost always allows users to select a model operating close to its optimal efficiency point. In addition to optimized hydraulics and impeller cutting, variable speed operation combined with a highly efficient drive system significantly contributes to lower energy and operating costs.

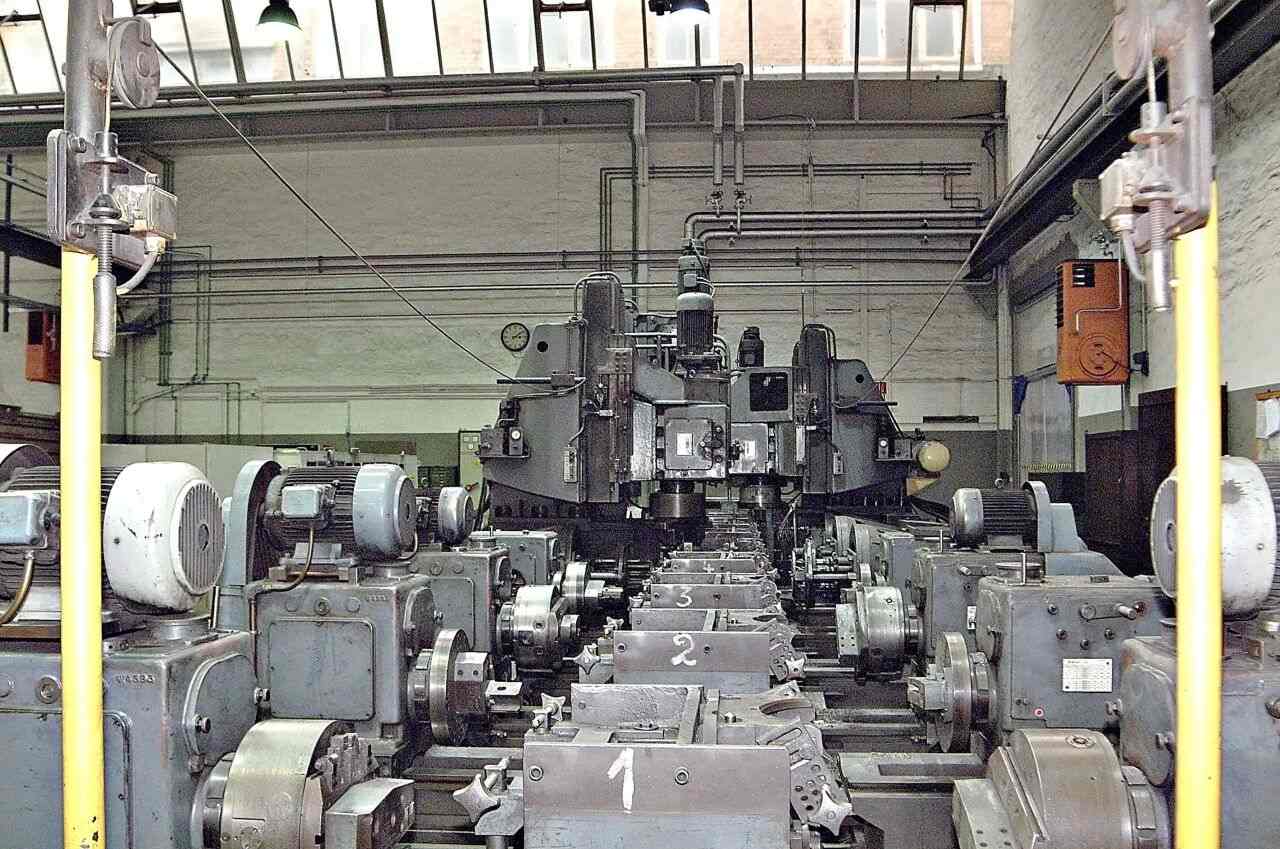

1955: The first automated production line for Eta components

Opening in Frankenthal

The Etanorm offers 62 sizes. To hydraulically optimize each size, we utilize advanced tools such as the Finite Element Method (FEM) and Computational Fluid Dynamics (CFD) to construct hydraulic profiles, which are then validated through comprehensive testing.

Although the Etanorm is a classic clean water pump and is not typically used for conveying media containing abrasive particles, given the increasing prevalence of solids in these applications, we have designed its shaft seal chamber to be more tolerant of solids-laden media than previous versions. At the same time, in order to make the water pump better adapt to the fluid being transported, users can choose different materials for the pump casing, impeller and mechanical seal.

Virtual Impeller Trimming for Maximum Flexibility

The next evolution of Etanorm is its integration with the Industry 4.0-compatible MyFlowDrive 2 drive system. This "virtual impeller trimming" feature allows users to independently set a desired fixed speed on the motor. The pump's flow rate can be easily increased or decreased at any time, providing users with a high degree of reliability and flexibility. Traditional fixed-speed pumps often have their impellers trimmed during manufacturing to match the design flow rate and head. This model requires significant time and effort to adjust later.

Because the synchronous motor's supply voltage is modulated by the motor's integrated frequency converter, it can be connected to virtually any power grid worldwide. This is a significant advantage for global general contractors: they no longer need to consider local grid voltage when selecting a pump.

With its broad selection and extensive material and seal options, Etanorm remains the preferred choice for efficient and economical fluid transport in numerous industries and applications.

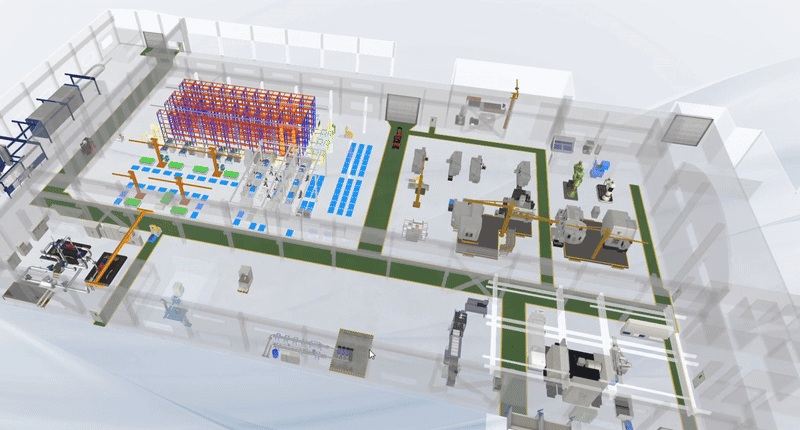

Investing in a Modernized Eta Production Line

To ensure the future competitiveness of the Frankenthal site, KSB is comprehensively modernizing its Eta production facilities according to the latest technology and energy standards, with completion scheduled for 2029. Starting in 2026, the Eta production facility at the Frankenthal headquarters will be expanded into a European competence center for the latest generation of electronically controlled pumps. KSB will invest approximately €70 million in this project over the next few years—one of the largest single investments in the company's history.

The new building will provide ample space for the reorganization of machining, assembly, and logistics areas, and the existing production hall will be fully renovated and reused. The energy-efficient production renovation also includes connecting the drying system in the new paint shop to the district heating network of the headquarters' new heating station and installing a photovoltaic system on the roof. KSB already produces the next generation of energy-efficient EtaLine Pro water pumps for the building services sector, manufactured using sustainable methods, at the Eta production site in Frankenthal.

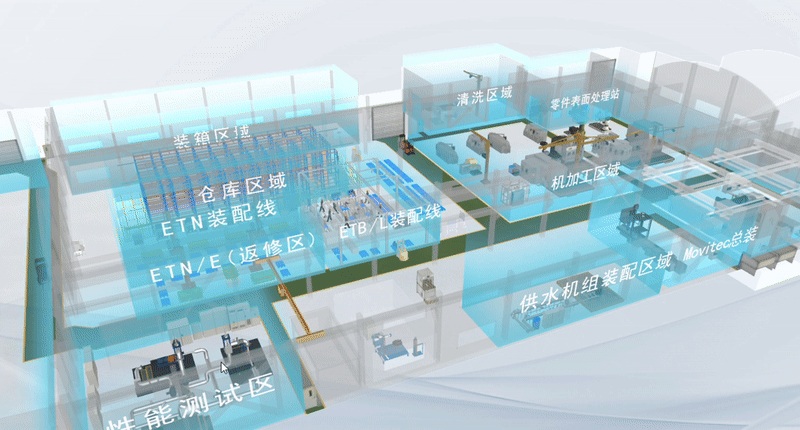

A live view of KSB's Eta production line in Shanghai

This global modernization strategy has also extended to China. Construction is currently underway at KSB's new Eta production line in Shanghai. Installation of the automated high-bay warehouse is nearly halfway complete, and the production line is undergoing final adjustments and construction.

Meanwhile, pre-acceptance of the production line's hardware has been successfully completed, and the equipment is about to be delivered to site, heralding a new level of localized production capacity for KSB in China.

Founded in Frankenthal, Germany in 1871, the KSB Group has grown over 150 years to become a world-leading supplier of pumps, valves, and services. Adhering to its brand philosophy of "Solutions. For Life," the Group employs over 16,000 people worldwide and operates in over 100 countries.