Adaptive N impeller helps small sewage pumps solve clogging problems

Clogging is a common problem in wastewater pumping, especially for smaller pumps due to their limited hydraulic space and lower torque. The consequences of clogging include increased energy consumption, additional maintenance, and emergency repairs, all of which lead to higher operating costs. Wastewater pump manufacturers are constantly developing better hydraulic designs to reduce clogging while maintaining high performance.

The Adaptive N Technology hydraulic design, an evolution of the self-cleaning N-type hydraulic design, is designed to address the challenges of anti-clogging in smaller pumps. It provides significant improvements in pump system reliability while reducing energy consumption and unplanned maintenance costs.

The Adaptive N impeller pump can be installed in wastewater pumping stations with or without screens, and is used to pump wastewater from homes, commercial buildings, hospitals, schools, and other locations. It can also be used in industrial wastewater and stormwater applications to transport wastewater that may contain solids, fibers, and other types of impurities.

A Flygt Concertor 6020 pump with Adaptive N technology installed

in a municipal wastewater pumping station.

Pumps Designed for Today's Wastewater Conditions

Since the early 20th century, pump designers have focused on reducing clogging by increasing flow rates. In mining, industrial, and raw water pumping applications, hard solids and spherical objects in the pumped medium are the most common clogging problems. Large impeller passages make it easier for these objects to pass through the pump. While conventional wastewater pumps are designed with large flow passages to avoid clogging, this has proven suboptimal for most wastewater applications.

At the same time, the risks posed by soft and fibrous objects—the most common solids in municipal wastewater—have been largely overlooked.

Detailed surveys and studies of modern wastewater indicate that wastewater almost never contains hard, spherical objects with a diameter as large as the internal diameter of the pipe system. Even when such objects enter the wastewater system, they typically settle or accumulate in areas of lower flow velocity, never reaching the pump.

A significant concern: Today's wastewater contains a higher proportion of soft objects. Examples include the growing variety of household and personal hygiene items, including paper towels, wet wipes, rags, dishcloths, and other fibrous objects. While much of this material should be disposed of as trash, many consumers flush it down the toilet. As a result, more fibrous, non-biodegradable material appears in the wastewater, further challenging the pump’s performance.

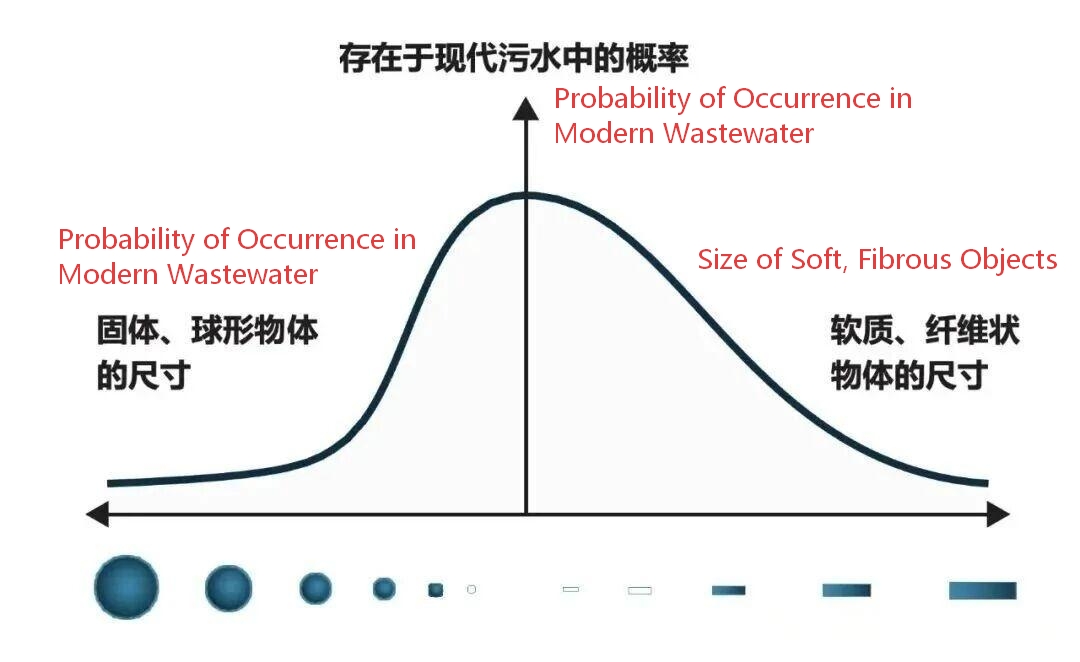

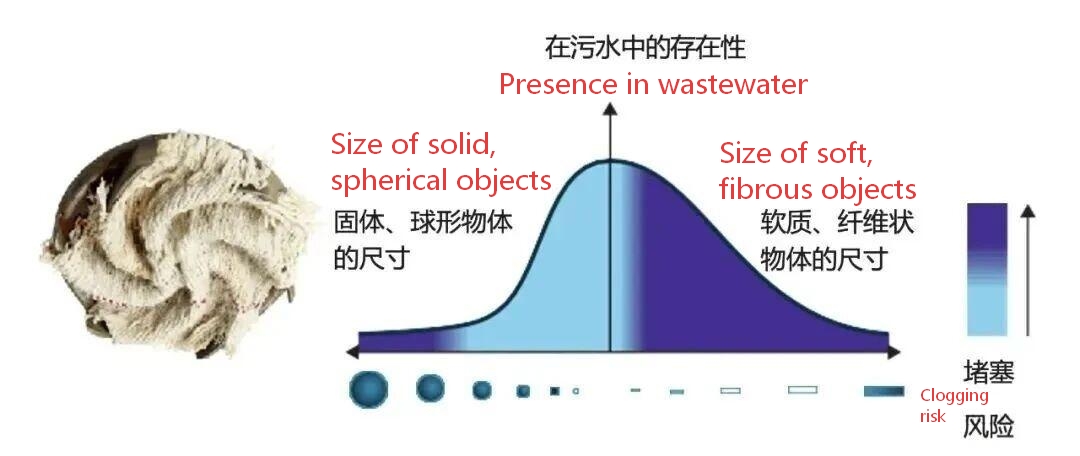

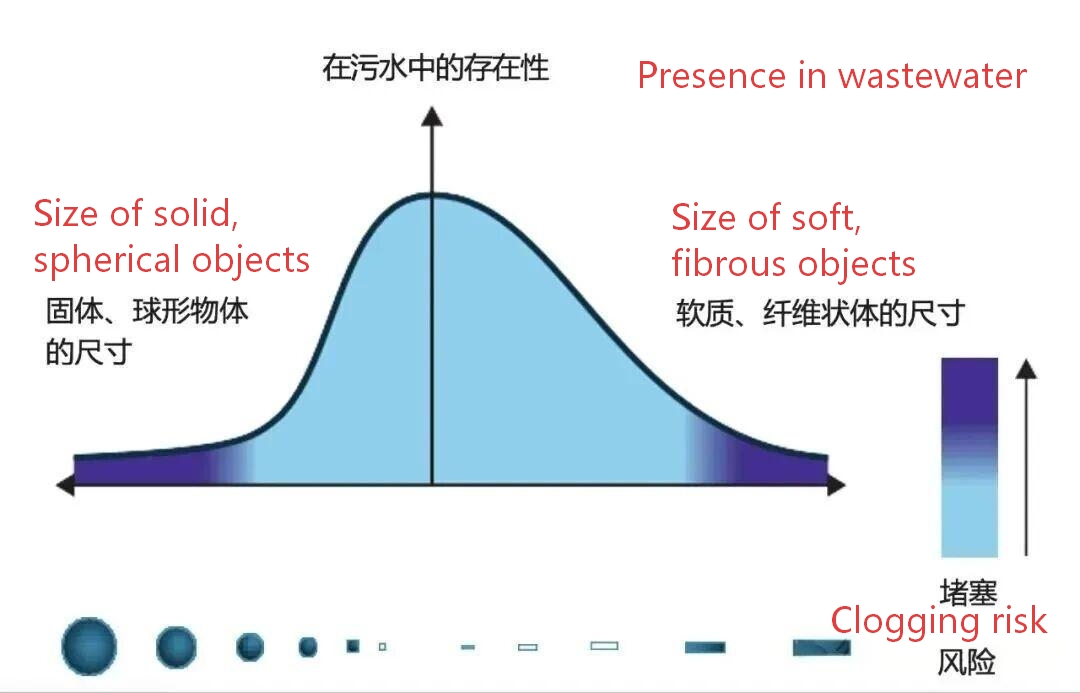

Figure 1: Likelihood of finding various types of solids in wastewater

Figure 1 is a conceptual illustration of the likelihood of finding different types of solids in wastewater. Hard, nearly spherical objects are on the left, while soft, elongated objects are on the right. As with many systems, the probability of finding very large objects (whether spherical or elongated) is very low. An important feature is that the distribution curve is asymmetric—it favors soft, elongated objects, which are the most common types found in wastewater today.

Soft vs. Hard Blockage

Research has shown that blockage problems are primarily caused by fibrous debris, which tends to become entangled around the leading edges of conventional impellers. The fibers wrap around these leading edges and fold over the sides of the blades. On straight and moderately curved leading edges, debris does not break off; instead, it continues to accumulate. This accumulation forms large clumps of solid material (sometimes called "cloth clumps"), which can lead to blockage.

As debris gradually accumulates around the leading edge of the impeller, the free path for water flow decreases, and pump performance degrades. This phenomenon is called soft blockage because it does not cause the pump to stop. The pump will continue to operate, but performance will be reduced to a certain degree. A typical effect of soft blockage is that the pump needs to run longer to pump a given volume of wastewater. A soft-blocked pump is also less efficient than an unblocked pump. Consequently, soft blockage increases energy consumption. Another consequence of soft blockage is increased vibration levels, which can accelerate wear on seals and bearings.

Small foreign matter can also become lodged between the volute and impeller, causing additional friction. The motor needs to provide greater torque to offset the braking effect, thus requiring higher input power. Once the operating current exceeds the trip current (causing the motor to overload), the pump stops operating. This is called a hard jam. A hard jam can also occur when a soft jam forms a noticeable mass. The primary impact of a hard jam is downtime and the need for unplanned repair services to clear the jam and restart the pump, increasing operating costs.

Dispelling Myths About Throughput Size

Decades of R&D experience, combined with hundreds of thousands of pump installations, have shown that focusing solely on throughput size is incorrect and misleading. Yet, it remains prevalent in wastewater pump purchasing specifications. User feedback and laboratory testing of conventional impellers have yielded the following results:

Channel Hydraulics' Anti-Clogging Performance

Channel impellers are single- or multi-blade, closed-circuit centrifugal impellers with large throughput sizes. They are highly efficient when pumping clear water but are susceptible to clogging when pumping wastewater.

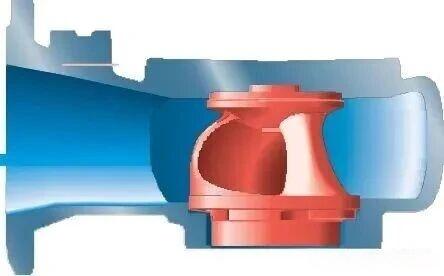

Figure 2: Example of a Single-Blade Impeller

Channel hydraulics are designed to achieve optimal clogging resistance at the pump's best efficiency point (BEP). Therefore, clogging resistance decreases as the operating point moves further from the BEP. The gradual accumulation of fibrous material on the leading edge (Figure 3) will cause pump efficiency to fall far below the factory-tested clear water value—a typical effect of soft clogging.

This design induces significant radial loads over long-term operation, placing greater stress on the shaft and bearings, increasing vibration and noise. Since the impeller can never be perfectly balanced, vibration is further exacerbated.

These problems ultimately lead to increased energy consumption, excessive wear, and shortened pump life.

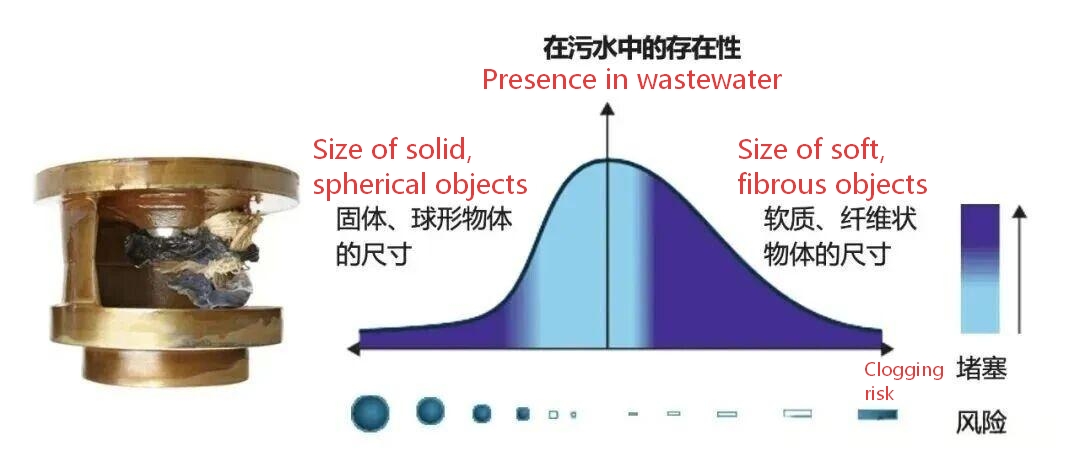

Figure 3: Clogging in a Channel Impeller

Clog Resistance of Vortex Hydraulics

Vortex impellers are located at a distance from the pump casing, providing ample volute space, but are inefficient when pumping both clean and dirty water.

Pump designers assumed:

• The rotating impeller would create a strong vortex within the volute, pumping out the liquid and any debris.

• The vortex impeller would operate like a torque converter, transferring energy from the impeller to the pumped medium with little or no fluid exchange.

• Because the impeller is outside the fluid flow path, objects never come into contact with the impeller, and the pump would not clog.

Figure 4: Example of a Vortex Impeller

However, vortex impellers function like other centrifugal impellers, meaning energy is transferred to the medium via the impeller blades. Therefore, multi-blade vortex impellers are very sensitive to soft clogging of the hub and leading edge. Its fluid dynamics (flow pattern and pressure distribution) can cause soft materials to accumulate on the impeller surfaces, further reducing the already low hydraulic efficiency.

Furthermore, vortex pumps often experience a large accumulation of solids in the volute, causing additional losses, increased power consumption, and ultimately leading to motor overload and pump shutdown.

Figure 5: Blockage in a vortex impeller

Anti-clogging of Modern Self-Cleaning Hydraulics

Research and investigations have shown that clogging problems are primarily related to the pump's difficulty discharging fibrous debris entangled on the impeller's leading edge. The N-type impeller features a state-of-the-art self-cleaning design developed in response to these findings. With a sharply swept horizontal leading edge and a relief groove, the N-type hydraulic design has proven to be a solution to most clogging issues. Furthermore, without the need for large flow passages, the impeller can be designed with multiple blades, which helps reduce radial forces, improve balance, and increase efficiency.

Figure 6 shows the clogging probability of the N-type impeller, which is significantly lower than that of conventional impellers designed around large flow dimensions.

Figure 6: Clogging in a Self-Cleaning N-Type Impeller

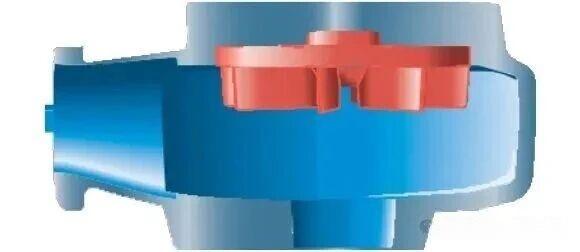

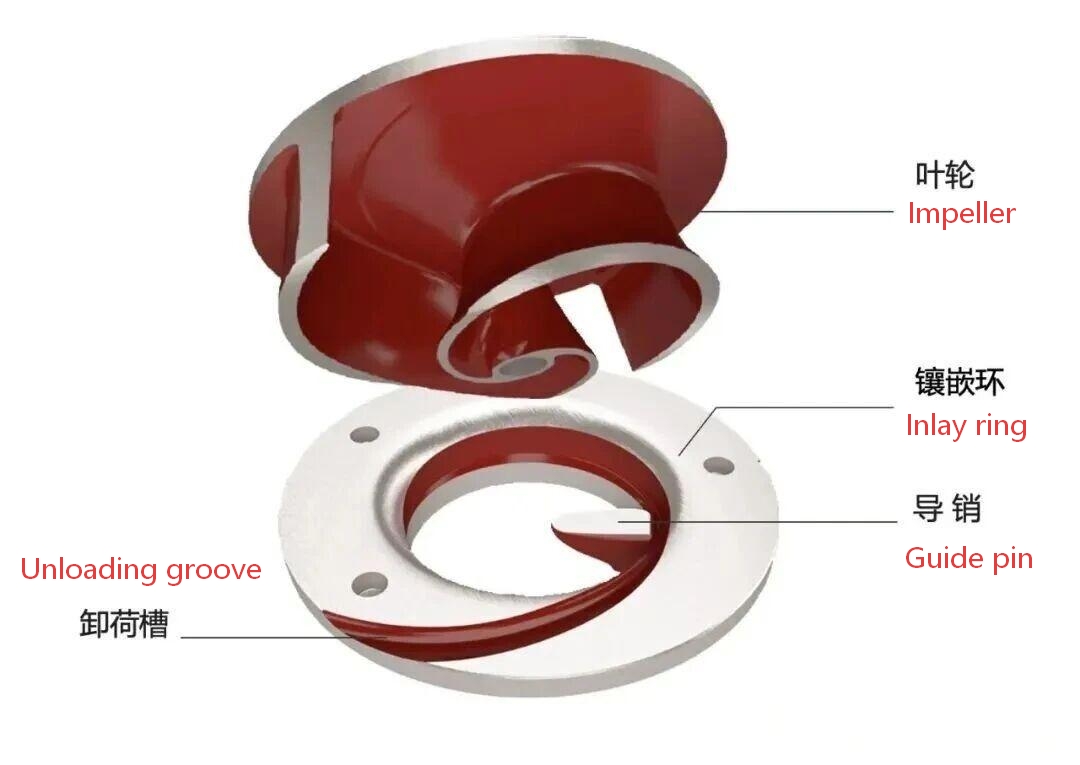

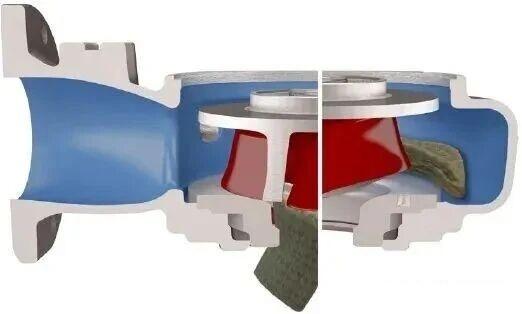

Figure 7: Self-Cleaning N-Technology Hydraulic Design

Figure 7 illustrates the N-type hydraulic design, which consists of a semi-open N-type impeller and an insert ring with guide pins.

The self-cleaning technology works as follows:

1. The N-type impeller blades, with their swept horizontal leading edges, achieve self-cleaning by sweeping solids from the center of the insert ring to the outer edge.

2. Unloading grooves in the insert ring work together with the horizontal leading edge to guide solids out of the impeller.

3. In smaller geometries, specially designed guide pins capture any fibers lodged near the impeller hub and allow the blades to push them out of the pump along the unloading grooves.

Thanks to its ability to expel hard objects, self-cleaning technology significantly reduces unscheduled maintenance and improves reliability. By preventing fibrous objects from tangling around the leading edge and causing soft plugging, the N-type impeller ensures sustained high efficiency over the long term, thereby reducing energy consumption.

Unlike channel hydraulics, the self-cleaning N-type hydraulic's anti-plugging properties are mechanically based and unaffected by flow rate variations. Therefore, the pump can operate efficiently at different points along the performance curve and, most importantly, with high reliability at a wide range of frequencies. Pairing the N-type hydraulic design with a variable frequency drive (VFD) enables better process control, energy savings, smoother operation, and reduced maintenance costs.

Development of the Self-Cleaning N-Type Hydraulic Design

Limited Torque in Small Pumps

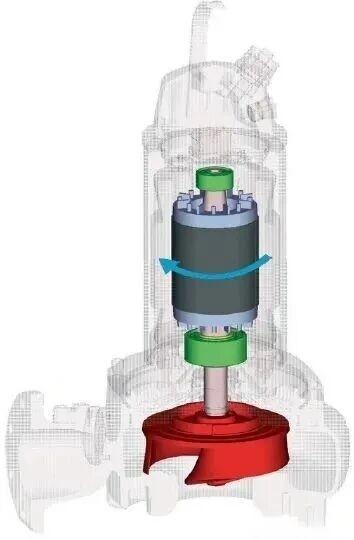

Submersible pumps are typically driven by an electric motor that is closely coupled to the pump impeller, as shown in Figure 8. When the pump starts, current flows into the stator windings, generating a rotating magnetic field that rotates the rotor via the shaft. Consequently, the motor generates torque proportional to the motor power. Torque is a physical quantity that defines the tendency of a force to rotate an object about an axis or point.

Figure 8: Torque Schematic

As previously mentioned, objects passing through the self-cleaning N pump are pushed along the unloading groove. Because the gap between the impeller blades and the insert ring is very small, only a few tenths of a millimeter, large debris is forced through the unloading groove. When this occurs, additional friction is generated, braking the impeller and slowing it down. The pump must provide additional torque to overcome this additional friction, which means higher motor torque is required. If the maximum motor torque is insufficient, debris will become stuck and the pump will stop. This is known as a hard jam.

Because motors used in submersible wastewater pumps are typically not significantly overrated, the maximum torque available at full power may not be sufficient to dislodge even the toughest debris. This is particularly true for smaller pumps, which often have relatively low torque margins. To further enhance the functionality of smaller N pumps, Flygt has developed Adaptive N technology to reduce the risk of hard jams caused by insufficient torque.

Adaptive N Technology

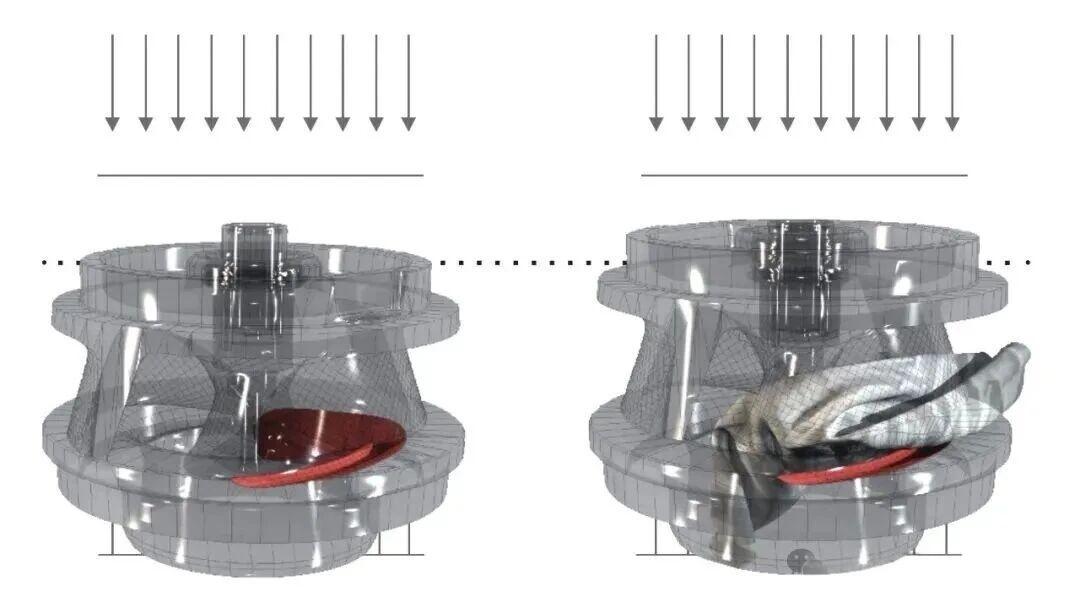

With Adaptive N technology, the N-type impeller is not completely fixed to the shaft: it can move axially up and down in response to the pressure differential created by large debris trying to pass through the pump. This movement temporarily increases the clearance between the impeller blades and the inlay ring. This allows even the largest pieces of cloth and the toughest debris to pass through the pump without requiring additional motor torque. This advantage is even more pronounced when the pump motor is operating on single-phase power, where available torque is further reduced.

Figure 9: Position of the Adaptive N Impeller During Operation

As shown on the left side of Figure 9, in most conditions, the Adaptive N impeller operates exactly like a conventional N-type impeller. However, when necessary, the impeller moves upward to pass larger debris, as shown on the right side of Figure 9.

The adaptive mechanism operates by exploiting the hydraulic pressure differential across the impeller. The pressure-dependent force is F=PxA, where P is the pressure and A is the area over which the pressure acts. Figure 10 shows how the combined forces determine the impeller's position.

The left side of Figure 10 is a conceptual image of the hydraulic pressure distributed across the impeller in lightly contaminated wastewater. At the base of the impeller, upward pressure increases with radius, so the force increases from the center of the impeller toward the edge. Meanwhile, at the top of the impeller, higher pressure acts evenly across the entire impeller disk. The net force acting on the impeller has a downward net value, maintaining the impeller in its normal operating position.

Figure 10: Force distribution during normal operation (left) and when a large piece of debris enters the pump (right)

When a large piece of debris enters the impeller, the force balance differs from normal operation. As shown on the right side of Figure 10, at the base of the impeller, a gradually increasing upward force is added to the hydraulic force. When the upward force exceeds the downward force, the impeller begins to move upward, and the gap between the impeller and the insert increases. When the gap is sufficiently wide, the debris passes through the impeller. The upward force then decreases, and the impeller returns to its original operating position.

Because this adaptive motion lasts only a fraction of a second, the momentary power increase has no significant impact on the overall efficiency of the pump. This adaptive feature also reduces loads on the shaft, seals, and bearings, thereby extending their service life.

In summary, Adaptive N technology significantly improves the self-cleaning capabilities of small pumps equipped with low-torque motors. Ultimately, reliable operation and consistently high efficiency reduce total cost of ownership.

Note: While there is a spring in the impeller hub, it is not related to the adaptive function. This spring keeps the impeller locked during assembly and shipping, preventing damage that could occur before installation.

Life Cycle Cost (LCC) Analysis for Small Wastewater Pumps

Life Cycle Cost (LCC) analysis is a methodology used to determine the total cost of a system over its lifecycle or to compare investment plans. A complete LCC analysis of any equipment includes all costs associated with the equipment, including initial investment, installation, operation, energy, downtime, environmental, maintenance, and disposal. The most significant components of the calculation will depend on the application, location, labor costs, and energy costs—factors that can vary significantly between markets.

A simplified analysis is often used when evaluating wastewater pump options. In this case, the most relevant factors are initial investment, energy costs, and maintenance costs (especially unplanned maintenance). Other factors can be excluded from the analysis.

Blockage is the most significant factor in unplanned maintenance costs. The number of times a pump blocks in a pumping station can vary significantly. The most common factors are:

• Type of pumped medium

• Type of pump hydraulic design

• Length of pump operating cycle

• Pump size

• Motor torque and moment of inertia

• Performance of routine maintenance

Increased energy costs due to soft clogging

As mentioned above, channel impeller pumps used in wastewater applications can suffer from soft clogging and may trip after a long operating cycle. However, vortex impeller pumps experiencing soft clogging may continue to operate due to the larger volume within the pump casing. This larger volume allows for greater accumulation of solids compared to other impeller types. In either case, soft clogging tends to reduce pump efficiency and induce hard clogging.

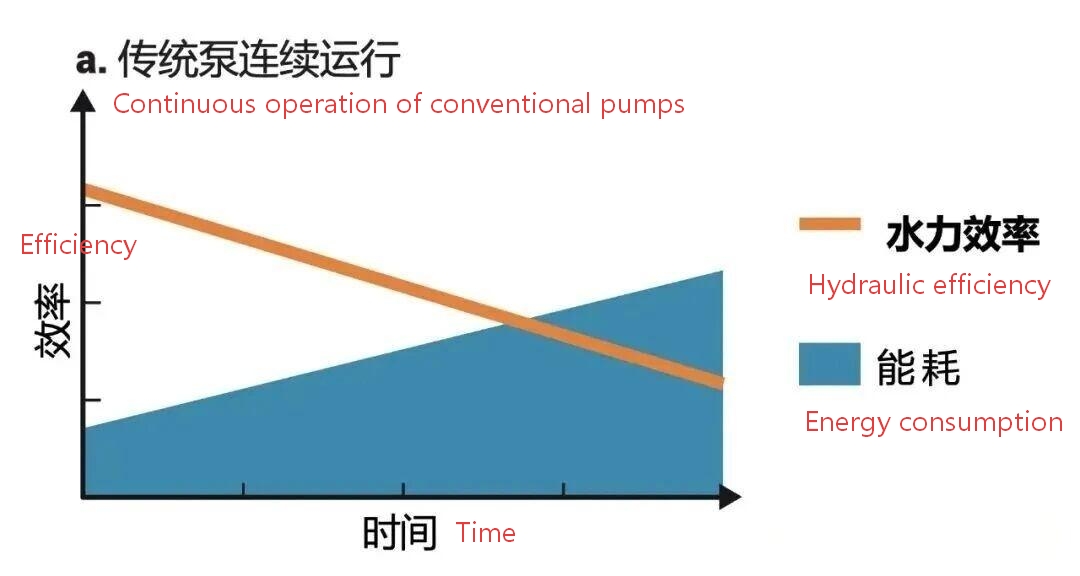

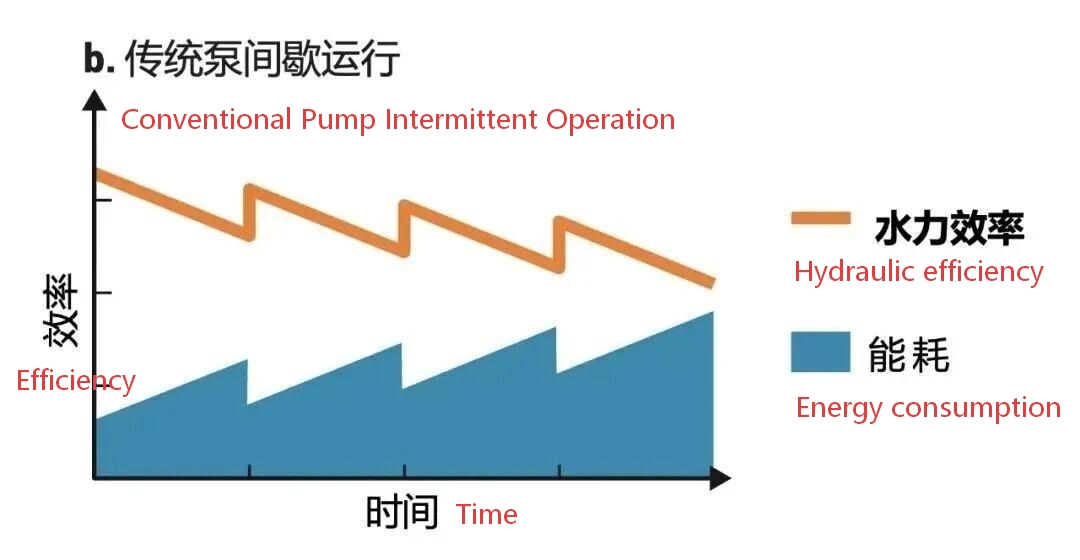

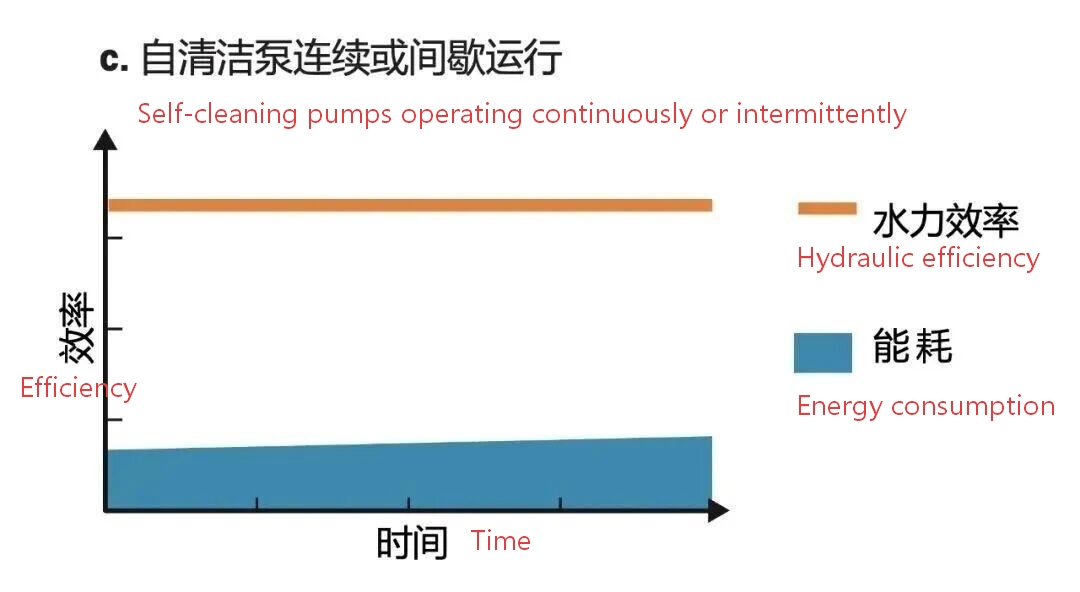

Figure 11 shows the impact of soft clogging on the efficiency and energy consumption of a conventional pump (channel or vortex hydraulic design) and a self-cleaning pump (N-type or Adaptive N Technology hydraulic design) over time.

As shown in Figure 11a, when the conventional pump is operated continuously in wastewater, its efficiency decreases and its energy consumption gradually increases. The same trend is observed when the conventional pump is operated intermittently (Figure 11b), even though backwashing can temporarily improve efficiency. In contrast, Figure 11c shows that the self-cleaning pump maintains consistent efficiency and energy consumption during continuous or intermittent operation in wastewater, resulting in the lowest energy consumption over time.

The increased energy costs due to soft clogging are easily measured on-site. However, predicting these additional costs is difficult due to variability in media properties and operating cycles.

Figure 11: Comparison of conventional pump performance and self-cleaning N-technology wastewater pump performance under two different operating scenarios

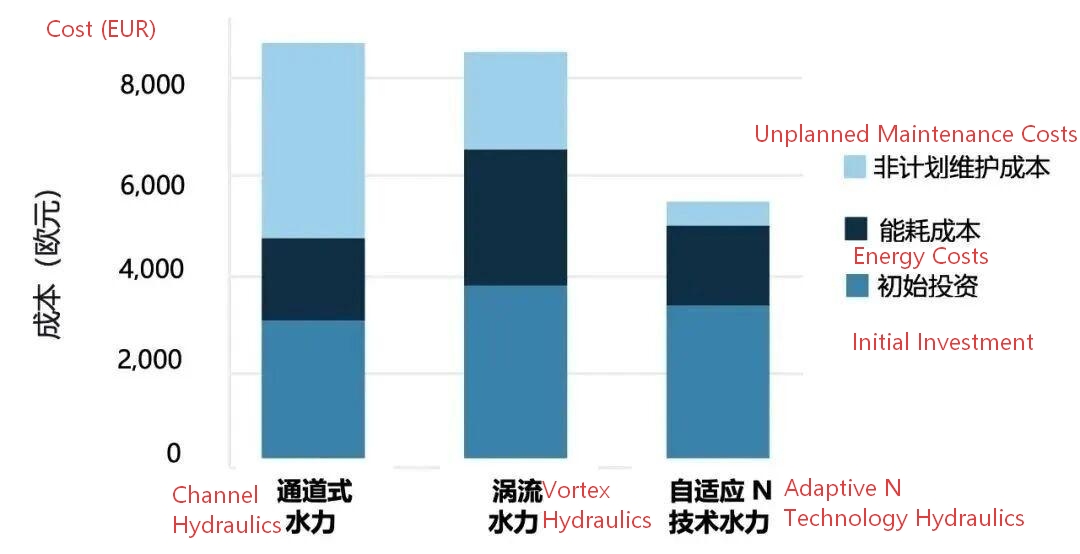

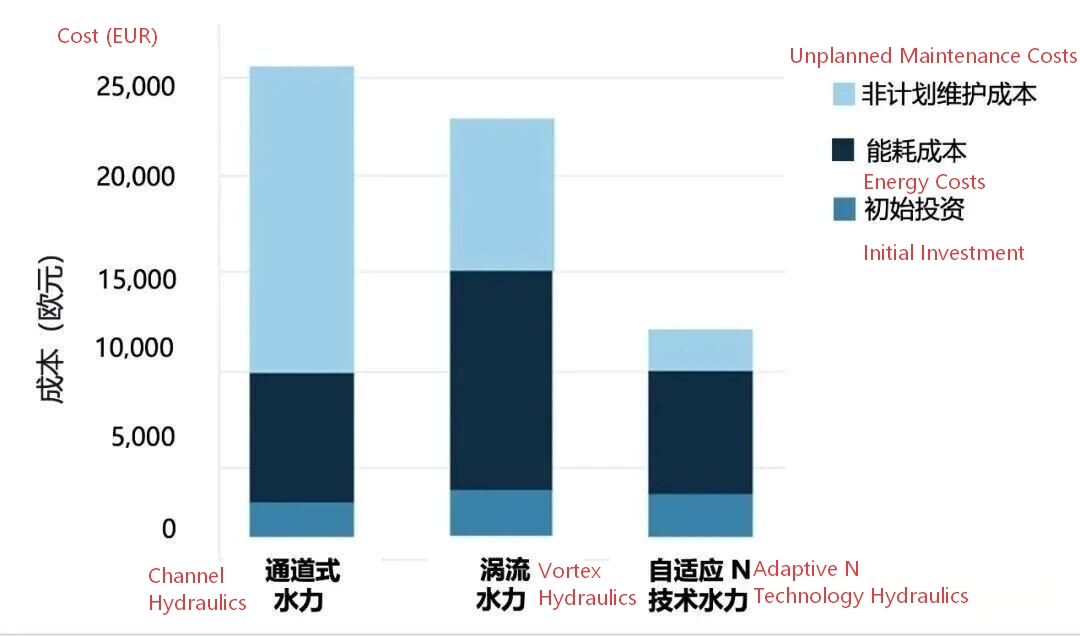

Simplified LCC Comparison Example

The following example provides a simplified LCC analysis comparing the costs of three pump types under short and long daily operating hours:

| Application and pumping details | |||||

| pumping medium | Raw sewage for grid | ||||

| Flow | 25 Liters/second | ||||

| Lift | 8 Meters | ||||

| Years of operation | 5 Years | ||||

| Energy cost* | 0.1 EUR/kWh | ||||

| Unplanned maintenance costs | 200 Euros/service | ||||

| Pump selection | Channel type impeller | Vortex impeller | Adaptive N impeller | ||

| Rated power(kW) | 3.1 | 4.7 | 3.1 | ||

| Hydraulic efficiency (clean water)** | 75% | 46% | 77% | ||

| Total efficiency (clean water)** | 63% | 38% | 65% | ||

| Specific energy consumption (kWh/m³)** | 0.0346 | 0.0574 | 0.0335 | ||

| Service times/year | Run 3 hours/day | 4 | 2 | 0.5 | |

| Run 12 hours/day | 16 | 8 | 2 | ||

*Energy costs can vary significantly by country.

**Efficiency and specific energy consumption data are based on Flygt pump performance curves.

In this example, the initial investment for the different hydraulic designs does not vary significantly. Over long operating cycles, the initial investment represents only a small fraction of the LCC. Furthermore, planned maintenance costs will be roughly the same across the various pump options. Meanwhile, unplanned maintenance costs due to hard clogging will have a greater impact on the LCC.

When a channel impeller pump is operated 12 hours per day for five years (Figure 14), its unplanned maintenance costs exceed five times the initial investment. In contrast, the Adaptive N-type impeller pump's maintenance costs are only 60% of its initial investment. While vortex impeller pumps are expected to require fewer services than channel impeller pumps, their lower efficiency than other hydraulic designs will result in higher energy costs. This does not even take into account the additional energy costs caused by soft clogging, which is difficult to predict and therefore not included in the LCC calculation or these charts. Taking this into account, the vortex hydraulic pump will have higher energy consumption than the other two hydraulic designs.

Whether operating 3 or 12 hours per day (Figures 13 and 14), the Adaptive N-type impeller pump has the lowest lifecycle cost in wastewater applications because it minimizes unplanned maintenance. If the additional energy costs caused by soft clogging are taken into account, the savings of the Adaptive N-type impeller pump are even greater than those shown in the LCC analysis. In addition to the economic benefits, the N-type pump provides a worry-free operation experience for the end user.

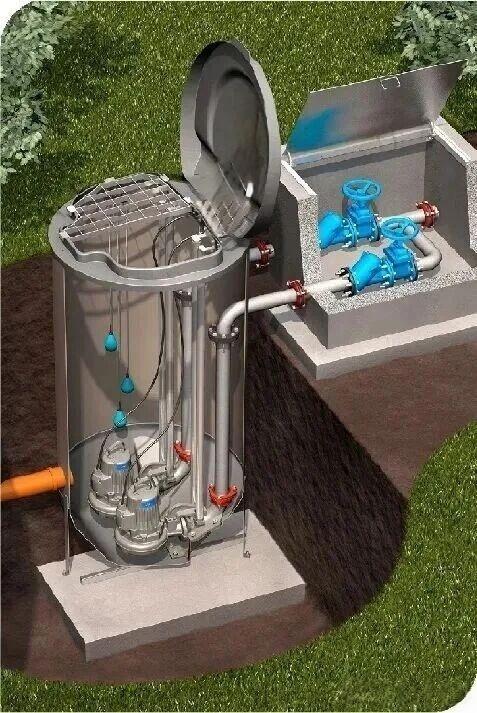

Figure 12: Example of a wet-well pumping station equipped with two small sewage pumps

Figure 13: Simplified LCC analysis based on 3 hours of daily operation for 5 years

Figure 14: Simplified LCC analysis based on 12 hours of daily operation for 5 years

Summary

The increasing focus on minimizing operating costs, particularly in sewage applications, has driven the demand for pumps with improved clogging resistance and higher efficiency. Twenty-five years ago, Flygt developed a self-cleaning hydraulic design to address this issue. The semi-open N-type impeller, featuring a swept horizontal leading edge and unloading grooves, significantly reduces the risk of clogging. Compared to traditional hydraulic designs, the N-type pump offers consistently high efficiency and improved reliability. As a result, the self-cleaning N-type pump has become popular worldwide.

Due to the limited size and motor torque of small sewage pumps, implementing N-type technology in the most challenging applications has been challenging. To further enhance the self-cleaning function, particularly to reduce the risk of hard clogging in relatively low-torque pumps, the N-type impeller incorporates adaptive technology. The adaptive N-type hydraulic design allows the impeller to move axially, allowing even the toughest debris to pass through. Extensive laboratory and field testing demonstrates that the Adaptive N technology hydraulic design effectively addresses both soft and hard clogging issues in small pumps.

Furthermore, LCC analysis demonstrates significant cost-saving potential for Adaptive N impeller pumps. In most cases, these savings come from lower energy consumption and reduced unplanned maintenance costs.