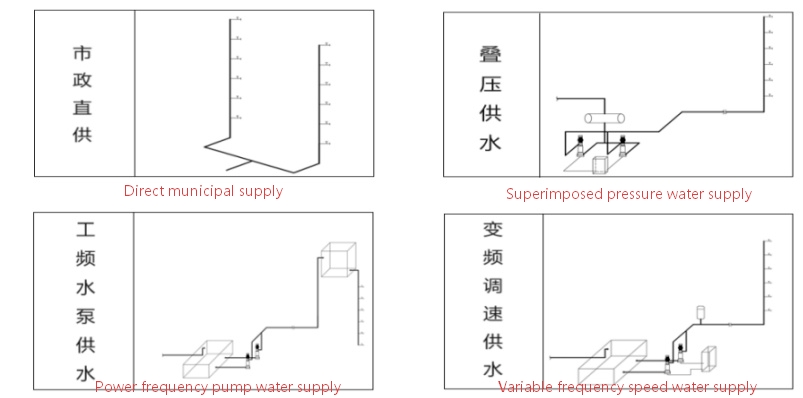

1. Municipal Direct Supply

Principle: Water is supplied through the municipal pipeline network to a water tank (or reservoir), which is then pressurized and pumped to the user's water point.

Components: Water tank (reservoir), pump, pipes, valves, etc.

Features:

Advantages:

Simple system with low investment cost.

The water tank can store a certain amount of water, allowing for temporary water supply during a municipal pipeline outage, ensuring continuous water supply.

Disadvantages:

The water tank requires regular cleaning and disinfection, otherwise it can easily breed bacteria and algae, affecting water quality.

It occupies building space (such as a rooftop or basement) and has certain structural requirements.

Applicable scenarios: Multi-story buildings, locations with low water quality requirements, or areas where municipal pipeline pressure is unstable but water storage is required.

2. Superimposed Pressure Water Supply

Principle: Directly connected to the municipal water supply network, water is supplied by superimposing the municipal water supply pressure through a flow stabilization tank and a water pump. No water tank is required (or only a small-volume flow stabilization tank is required).

Components: Flow stabilization tank, water pump unit, pressure sensor, negative pressure prevention device, control cabinet, etc.

Features:

Advantages:

No large water tank required, saving building space and reducing the risk of water contamination.

Overlay water pressure utilizes municipal pipe pressure, resulting in significant energy savings (approximately 30%-50% energy savings compared to traditional variable-frequency water supply).

Easy installation and a small footprint make it suitable for retrofit projects.

Disadvantages:

Limited by municipal pipe pressure, low pressure may affect water supply to surrounding users.

Requires high municipal pipe water quality (not suitable for use in areas with easily contaminated water).

Applicable Scenario: Areas with stable municipal pipe pressure and good water quality, particularly suitable for high-rise buildings with high water quality requirements and limited space (such as residential communities and commercial complexes).

3. Industrial Frequency Water Pump Supply Method

Principle: A water pump operates at a fixed speed under a constant industrial frequency power supply (typically 50Hz AC). The centrifugal force generated by the rotating pump impeller pressurizes and delivers water to the pipe network. Its core characteristic is that the pump speed is constant, and the water flow rate is primarily regulated by valves (such as throttle valves and check valves). The speed cannot be adjusted in real time based on water consumption, making this a traditional fixed-speed water supply method.

Components: Flow stabilization tank, pump unit, pressure sensor, piping system, valves, and control devices.

Features:

Advantages:

Simple system structure, no complex variable frequency control system or pressure sensor required, minimal equipment, and easy installation and commissioning.

Low initial investment cost, eliminating expensive equipment such as frequency converters and intelligent controllers, resulting in significantly lower hardware costs than variable frequency water supply systems.

Stable operation, stable mains power supply, and no electromagnetic interference or control system failures that can occur with variable frequency equipment.

Disadvantages:

High energy consumption, poor economic efficiency, inability to adjust speed based on water consumption, and constant operation at maximum power. When water consumption decreases, valves must be used to throttle and reduce pressure, resulting in a "big horse pulling a small cart" phenomenon and significant energy waste. (Statistically, compared to variable frequency water supply, mains frequency water supply may consume more energy.) 30%-50%).

Water pressure fluctuates significantly. During peak water usage, insufficient pump output can cause a drop in water pressure, resulting in insufficient water supply to high-rise users. During low water usage, excessive pressure in the pipe network can damage pipes or water-using appliances (such as faucets and water heaters).

4. Variable Frequency Drive Water Supply Method

Principle: The frequency converter controls the pump speed, adjusting the water supply pressure in real time based on water consumption to maintain constant pipe network pressure.

Components: Pump unit, frequency converter, pressure sensor, control cabinet, piping, etc.

Features:

Advantages:

High efficiency and energy saving, on-demand water supply, and avoids the "high-pressure throttling" problem of traditional water supply methods. This reduces energy waste.

The high degree of automation eliminates frequent manual operation, resulting in stable pressure and a superior water experience.

The low starting current of the pump reduces mechanical wear and extends equipment life.

Disadvantages:

High equipment investment (requires inverters, control cabinets, etc.).

High control system stability requirements, requiring specialized maintenance personnel.

Applicable scenarios: High-rise buildings, locations with high water consumption and high water quality requirements (such as hotels, hospitals, and office buildings), or areas with insufficient municipal pipe pressure but requiring a stable water supply.