What are the wrong ways to use a pump?

As a key component for water transportation and pressure boosting, pumps play a vital role in water supply systems. However, they frequently encounter operational issues, most of which stem from improper usage. Years of practical experience have identified ten common misuse patterns in pump operation.

1.Overload

Whether it is flow, pressure or speed, long-term excessive deviation from the rated design point of work, may lead to increased pump load, such as centrifugal pump full open power maximum, shorten its life, or even "death".

2. Difficulty in medium inhalation

● The imported liquid level is too low, which is easy to produce vortex, suck in air, resulting in cavitation, flow head reduction;

● The inlet pipe or inlet is blocked by foreign matter, resulting in reduced flow and head;

● When the medium temperature increases, the vaporization pressure of the medium increases, and the cavitation margin decreases, resulting in the decrease of the suction stroke;

● The inlet pipe is unreasonable (such as: too many elbow joints of the inlet pipe, the pipe diameter is smaller than the pump inlet), the pipeline loss increases, and the cavitation margin decreases, which is easy to cause cavitation;

● The installation altitude of the pump is increased, the atmospheric pressure is reduced, the cavitation margin is reduced, resulting in the suction stroke is reduced.

3. Close the valve only, and the water pump is not powered off

In addition to automatic pumps and intelligent pumps, ordinary water pumps are operated for a long time under closed valve conditions, and there is no bypass. All the energy consumption of the system is wasted in "heating" water, resulting in pump cavitation, which causes unstable operation of the pump and even accidents.

4. CORROSION

The conveyed medium may corrode flow components and mechanical seals. For example, hydrochloric acid corrodes stainless steel, and hydrofluoric acid corrodes silicon carbide.

Note: The corroded surface will appear with a dense array of pinholes of varying sizes, resembling the surface of the moon.

5. Erosion

The liquid carrying solid particles will continuously wash the pump chamber, impeller and other flow components, so that the pump's service flow, head and life are reduced.

Note: In case of severe abrasion, fish scale pattern will appear on the abraded surface.

6. Pump body cracking

Due to the blockage of export or the high pressure of import, or the freezing of liquid in the pump chamber due to low temperature, the actual pressure of the pump chamber is far higher than its bearing pressure, and finally the pump body cracks.

7、vibrate

The pump is installed on a rigid foundation, lacking vibration damping measures, or the foundation is too weak to provide sufficient strength. The inlet and outlet pipelines lack support, resulting in uneven force on the unit, which binds the pump's operating vibration, and the pump "jumps" like on a trampoline.

8. Dampness

● The onshore pump is in a wet environment for a long time or the mechanical seal fails, and the liquid leakage splashes to the motor's non-sealed part.

● The sealing of the submersible pump is failed, the cable is not sealed, the pump is exposed to moisture in the humid environment or the cable is dropped into the pool, resulting in liquid intrusion into the motor chamber.

Note: If there are water stains and condensate beads in the motor and the insulation resistance is less than 50 megohms, it is considered to be damp.

9. Irregular inspections

Pumps never get enough "care". They are not checked and maintained regularly according to the instructions, the machine seal is not replaced irregularly, the iron pump and aluminum pump are not repainted, and the vibration is not checked, so that the pump from "minor disease not treated" to "major disease not treated".

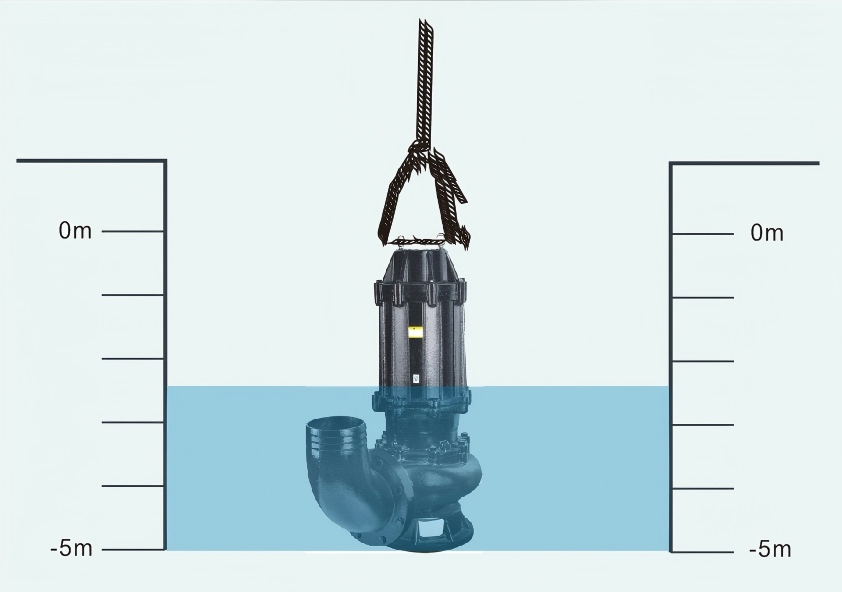

10. Poor heat dissipation

● The submersible electric pump motor is exposed to the water surface for dehydration operation, or sunk in the mud, so that the motor heat dissipation is slow, easy to cause burning, especially the oil-filled motor heat dissipation is bad, there is a chance of explosion.

● The onshore pump is installed in the corner or in the closed box, and the fan cannot ventilate the surrounding air, resulting in poor heat dissipation of the motor.