Ways to reduce maintenance costs of mechanical seals

Jul 25, 2025

Mechanical seals are essential to the smooth and reliable operation of industrial pumps. Their performance directly affects the overall efficiency and maintenance costs of the equipment. Once a mechanical seal fails, it can cause significant financial losses, especially if the root cause is not promptly addressed. Experts in the field point out that premature failure of mechanical seals is usually not due to inherent defects in the seal itself, but to external factors.

The main reason for mechanical seal failure is the lack of a stable liquid film between moving parts. This emphasizes its importance in the entire system. The root cause of the unstable liquid film must be identified and resolved to ensure long-term reliable performance of the mechanical seal.

The following table summarizes the key factors that lead to mechanical seal failure:

Table 1 Key factors leading to mechanical seal failure

PHASE

Causes of failure

Results

Impact

%

Selection

Incorrect selection of materials and sliding surfaces

Chemical attack, corrosion

Liquid film evaporation

B

10%

Incorrect selection of flushing plan

Mechanical seal overheating

A

Incorrect selection of mechanical seal type

Seal Deformation of cover, abnormal behavior

A

Installation

Incorrect installation of mechanical seal

Degraded mechanical seal performance, working conditions do not meet specification requirements

A,C

20%

Incorrect installation of flushing/cooling system

Inadequate flushing leads to overheating of mechanical seal

A

Start-up and stable operation

Foreign particles in pipeline or plant

Wear and damage of sealing ring

Inadequate flushing

Overheating of mechanical seal

A

60%

Air pockets in machine or equipment

Overheating of mechanical seal

A

Incorrect setting of auxiliary systems

Overheating of mechanical seal

A

Incorrect machine calibration and centering

Instability of liquid film

A

Excessive vibration

Instability of liquid film

Damage to sealing surface

A

Start-up under dry-running conditions

Overheating, abnormal wear

A

Operation not in accordance with technical specifications

Degraded mechanical seal performance

A

Post-processing

Inadequate machine maintenance

Degraded mechanical seal performance

A,B,C

10%

Incorrect refurbishment of mechanical seal

Degraded mechanical seal performance

A,B,C

Incorrect installation after refurbishment

Degraded mechanical seal performance

A,C

Reasons for mechanical seal failure include:

A) Missing or unstable film between the seal surfaces

B) Damage

C) Excessive leakage

How to reduce the maintenance cost of mechanical seals

In-plant maintenance can reduce costs. To achieve this, there are two important factors:

- Technological development

- Standardization and interchangeability

Technological development

A mechanical seal consists of a rotating part (rotating ring) and a fixed part (stationary ring). The rotating ring is usually connected to the rotating part of the equipment (such as the shaft), while the stationary ring is connected to the fixed part of the machine (such as the stuffing box of a rotary pump). To ensure effective sealing performance, the sealing surfaces must be absolutely flat and the surface roughness must be extremely low. The rotating and stationary rings with precisely matched dimensions can fit tightly and effectively prevent the leakage of process fluids.

The interaction between the two sealing surfaces determines the hydraulic balance state of the mechanical seal. Under normal working conditions, the liquid film formed can achieve a hydraulic balance between the opening and closing forces generated by the pressure of the sealing fluid, thereby limiting physical leakage. The API 682 standard provides detailed guidance and specifications on how to calculate the correct sizing parameters.

However, during operation, the seal ring may deform due to mechanical and thermal stress, which can affect the performance of the mechanical seal. This deformation can disrupt the original hydraulic balance, making the liquid film between the sealing faces unstable, which in turn leads to excessive leakage.

Therefore, engineers continue to explore new technical methods to reduce friction, especially in critical application conditions, with special attention to the development of new materials and the application of new sealing technologies. These innovations have significantly improved the sealing efficiency and reliability in modern production processes.

Non-contact technology - sliding end faces with grooves

The non-contact mechanical end face seal system consists of a dynamic ring and a static ring. The end face of the dynamic ring is specially processed with a specific geometry (such as spiral or stepped) to generate a fluid dynamic effect between the two end faces, thereby forming a stable small gap between them (refer to Figure 1). This design uses the principle of fluid dynamic lift, so that the sealing faces can maintain an effective sealing state without direct contact.

Unlike traditional contact seals, this non-contact design does not rely on a liquid barrier and its related support system. Instead, it achieves the sealing effect by supplying an inert gas to the sealing interface. The selection of inert gas is usually based on its chemical stability and adaptability to the working environment to avoid reaction with the sealed medium. In addition, the pressure and flow of the inert gas can be precisely controlled through a simple control panel to ensure the stability and reliability of the sealing performance.

Since the friction coefficient and wear of the seal can be effectively reduced to near zero, this solution is very suitable for application scenarios that require significant energy saving, especially in the oil and gas, petrochemical and pharmaceutical industries that require zero emissions.

Figure 1: Spiral groove face ring

New generation of materials

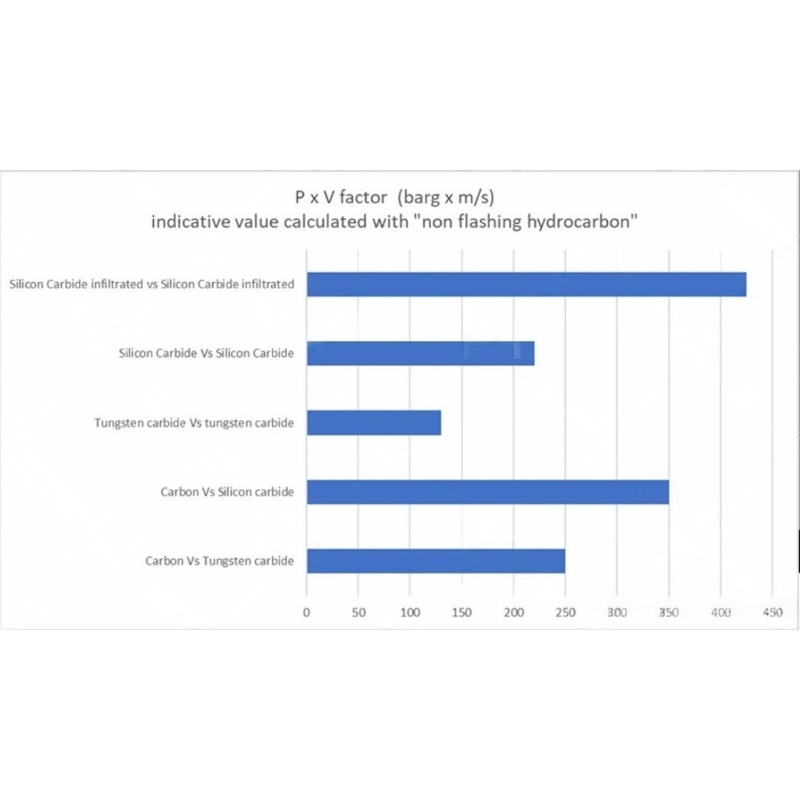

SiC materials with self-lubricating properties are widely used in mechanical seals. When choosing the pairing of moving parts, materials of different hardness are usually used to minimize friction. The choice of sealing ring combination is particularly critical, with the most common combination being carbon rings and silicon carbide rings (see Figure 2, Pressure x Velocity - PxV coefficients for common face combinations). This combination not only has excellent thermal conductivity and chemical resistance, but also effectively resists wear caused by abrasive particles in the fluid.

When graphite rings and silicon carbide rings deform for various reasons, they show excellent mutual adaptation and maintain good sealing performance. However, in the case of very high operating pressures or when the fluid contains a lot of dirt, two high-hardness rings must be used to ensure the sealing effect. Although these materials have a high friction coefficient, this leads to high heat generation during rotation, which may cause evaporation of the liquid film, resulting in dry running, ring deformation or fracture, and affecting the performance of the auxiliary gasket.

A recently developed manufacturing process adds self-lubricating material particles to the sintered silicon carbide matrix by impregnation (SiC impregnation). The stationary and rotating rings made in this way can reach extremely high performance limits. Specifically, mechanical seals using this material are able to limit the amount of torque absorbed, significantly reducing friction and heat generation. This not only improves the durability and reliability of the sealing components, but also extends their service life, especially for applications under extreme working conditions.

Figure 2: P x V coefficient graph

Diamond-coated seal faces

Silicon carbide rings are usually coated with a thin layer of diamond coating by chemical vapor deposition (CVD) to enhance their tribological properties and chemical compatibility. In hot water applications in power plants and in oil and petrochemical facilities, liquid gases tend to evaporate, resulting in loss of lubrication properties, and diamond coatings can significantly improve the wear and corrosion resistance of seals.

In the pharmaceutical industry, traditional seals often fail to meet the stringent requirements due to the need to avoid any contamination, while diamond-coated seals show excellent chemical inertness and purity, fully meeting these high standards.

In addition, mechanical seals with diamond-coated rings can withstand short-term operation under dry-running conditions of double seals and non-contact seals, further expanding their application range.

Engineering machinery seals

Maintaining the consistency of the cross-sectional area of the seal ring is a major challenge during the design stage (see Figure 3). This consistency is essential to ensure the driving stability of the seal ring and prevent reverse rotation. Such seals are currently widely used in boiler feed pumps, pipelines, water injection systems, multiphase pumps and other high-pressure applications with operating pressures exceeding 100 bar. Precisely controlling the size and shape of the seal ring not only helps maintain sealing performance, but also effectively reduces wear and extends service life.

Sliding surface behavior under high pressure stress

And sliding surface shape with limited deformation under high pressure

Figure 3: Optimal design of sealing ring

Standardization and Interchangeability

Mechanical seal assemblies, like other industrial parts, have a reference standard that specifies their installation dimensions, allowing seals from other manufacturers to be substituted. This not only improves the quality of service for the end user, but also reduces plant operating costs.

EN 12756 Standard

The EN 12756 standard specifies the main installation dimensions for single and double mechanical seals when used as assemblies, excluding flanges and sleeves covering rotating and stationary parts. The first mechanical seals were introduced to Europe from the United States in the early post-war period, with dimensions in inches.

DIN 24960, which later evolved into EN 12756, brought great benefits to manufacturers of pumps produced to ISO standards, and especially to end users, as they were no longer restricted to seal suppliers that offered non-standardized products. The price of seals and their associated maintenance costs were thus significantly reduced.

API Standard

Pumps in oil and gas equipment are usually manufactured to API 610, while mechanical seals are usually manufactured to API 682. According to the standard, seals must be supplied in the form of cartridge assemblies, i.e. complete with flange and sleeve, to simplify installation and allow testing before delivery. The API standard provides recommendations for determining mechanical seal dimensions based on the stuffing box specifications of different API pumps on the market.

This standardization is not only technically feasible, but also allows the overall dimensions of the components in the stuffing box to be standardized, thus enabling medium-sized batch production and reducing manufacturing and warehouse management costs.

Importantly, this standardization allows end users to choose different "qualified mechanical seal manufacturers", thus eliminating interchangeability issues. In this way, users have the flexibility to choose the right seal and ensure that it can be replaced smoothly, reducing downtime and maintenance costs caused by seal mismatches.

Read More